Gas turbine flow meter

- Commodity name: Gas turbine flow meter

- Product Description

-

Introduction

The gas turbine flowmeter is a velocity-type flow instrument that accurately measures gas flow. It has advantages such as simple and lightweight structure, high measurement accuracy, good repeatability, wide measurement range, and convenient installation and maintenance. It is widely used in various gases in industries such as petroleum, chemical, metallurgy, aviation, scientific research, etc., including natural gas, city gas, propane, butane, air, nitrogen, and more. Due to its high accuracy and good repeatability, it is suitable for trade measurement and industrial process monitoring.

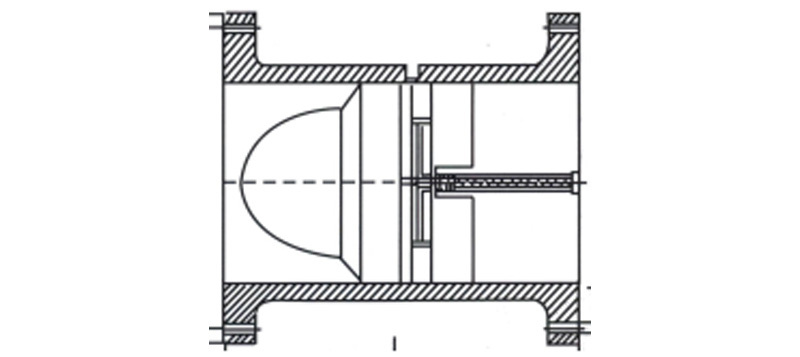

Working Principle

When the gas flow enters the flowmeter housing, under the action of the fluid, due to the angle between the turbine blades and the fluid flow direction, a torque is generated on the turbine. The turbine starts to rotate after overcoming the resistance torque and friction torque. When the torques reach equilibrium, the rotation speed stabilizes, and the turbine's rotational speed has a linear relationship with the flow rate. The magnets on the rotating signal disk periodically change the magnetic resistance of the sensor, thereby inducing a pulse signal at both ends of the sensor that is proportional to the volumetric flow rate of the fluid. This signal is amplified by a preamplifier and processed together with pressure and temperature signals detected by pressure and temperature sensors to directly display standard volumetric flow rate and total standard volume.

Product Features

1. High accuracy, good repeatability, low pressure loss, good shock resistance;

2. Uses high-quality bearings with low friction resistance and good sealing;

3. Integrates microprocessor, flow sensor, high-precision temperature and pressure sensors to directly measure the flow rate, temperature, and pressure of the measured gas while automatically performing flow tracking compensation and compressibility factor correction calculations;

4. The instrument has pulse signal and analog signal output, which can be centralized for data collection and real-time management through RS485 communication interface or system;

5. Low power consumption; can be powered by an internal battery or external power supply; field display type LCD screen is clear and intuitive with low power consumption; a 3V lithium battery can operate for over 5 years;

6. Has real-time data storage function to prevent data loss during battery replacement or sudden power failure; internal data can be permanently saved during power outage;

7. Can be used with IC card prepaid systems for convenient trade settlement;

8. Made of 1Cr18Ni9Ti stainless steel structure (turbine uses 2Cr13) with good corrosion resistance;

9. Easy to maintain with a self-rectifying structure; small and lightweight with a simple design that allows for quick assembly and disassembly; internal cleaning is straightforward;

10. Strong anti-magnetic interference and shock resistance; reliable performance with long service life;

11. Low lower limit flow rate with a wide measurement range;

Main Technical Parameters

1. Standard: GB/T 18940-2003 'Measurement of Gas Flow in Closed Pipelines - Turbine Flowmeter'

2. Accuracy LevelLevel 1.0: Qmax-0.2max ±1.0% 0.2max-Qmin ±2.0%

Level 1.5: Qmax-0.2max ±1.5% 0.2max-Qmin ±3.0%

3. Nominal Diameter: 25mm~300mm;

4. Measured Medium: Natural gas, coal gas, air, etc.;

5. Ambient Temperature: -20℃~+50℃;

6. Measured Medium Temperature: -20℃~+80℃;

7. Nominal Pressure: 1.6MPa, 2.5MPa, 4.0MPa;

8. Explosion-proof Mark: ExibⅡBT4 ExdⅡBT6;

9. Output Signal: Voltage pulse, 4~20mA;

10. Communication Interface: Optional RS-485 communication interface;

11. Power Supply: Sensor: +5V~+24VDC (external); Transmitter: +24VDC (external), Flowmeter: 3.0V lithium battery (built-in).

Instrument Selection

1. Selection Parameter Table

LWGQ□ [□□□] [□] [□] [□] [Description] [Type]

[Model][LWGQ] [Basic model], +12V power supply, pulse output, high level ≥8V

[Low level ≤0.8V][LWGQA] [4~20mA two-wire current output, remote transmission type] [LWGQB] [Battery-powered field display type] [LWGQC] [Field display/4~20mA two-wire current output] [Nominal]

[Diameter]

[25mm], ordinary turbine flow range of 2~20m3/h

[Wide range turbine of]4~40m3/h25 [40mm], ordinary turbine flow range of]3~50m3/h

[50mm], ordinary turbine flow range of]5~100m3/h40 [Wide range turbine of]10~150m3/h 50 50mm,普通涡轮流量范围5~100m3/h

宽量程涡轮为10~150m3/h80 80mm, the normal turbine flow range is 10 to 240 m3/h

The wide range turbine is 20 to 480 m3/h100 100mm, the normal turbine flow range is 12 to 360 m3/h

The wide range turbine is 20 to 600 m3/h150 150mm, the normal turbine flow range is 25 to 1000 m3/h

The wide range turbine is 40 to 1500 m3/h200 200mm, the normal turbine flow range is 50 to 2000 m3/h

The wide range turbine is 75 to 2500 m3/h250 250mm, the normal turbine flow range is 80 to 3500 m3/h

The wide range turbine is 160 to 4000 m3/h300 300mm, the normal turbine flow range is 300 to 6500 m3/h Explosion-proof

ExplosionNo marking, non-explosion-proof type B Explosion-proof type Accuracy

LevelA Accuracy level 1.0 B Accuracy level 1.5 Turbine

TypeA Wide range turbine B Normal turbine 2. Flowmeter selection

2.1. Scope of use

a. The required flow range should be less than the selection parameter table, and there are strict requirements for starting flow;

b. There should be no short intervals and large fluctuations in fluid media;

c. Suitable for natural gas, city gas, compressed air, nitrogen, etc.

2.2. Determination of specifications

Users should estimate the maximum and minimum volumetric flow of the pipeline based on the gas transmission volume, possible temperature and pressure ranges of the medium, and correctly select the flowmeter specifications. When both sizes of flowmeters can cover the minimum and maximum volumetric flow, a smaller diameter should be selected within allowable pressure loss. Calculate the flow range under working conditions based on the flow range and medium pressure under standard conditions.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.