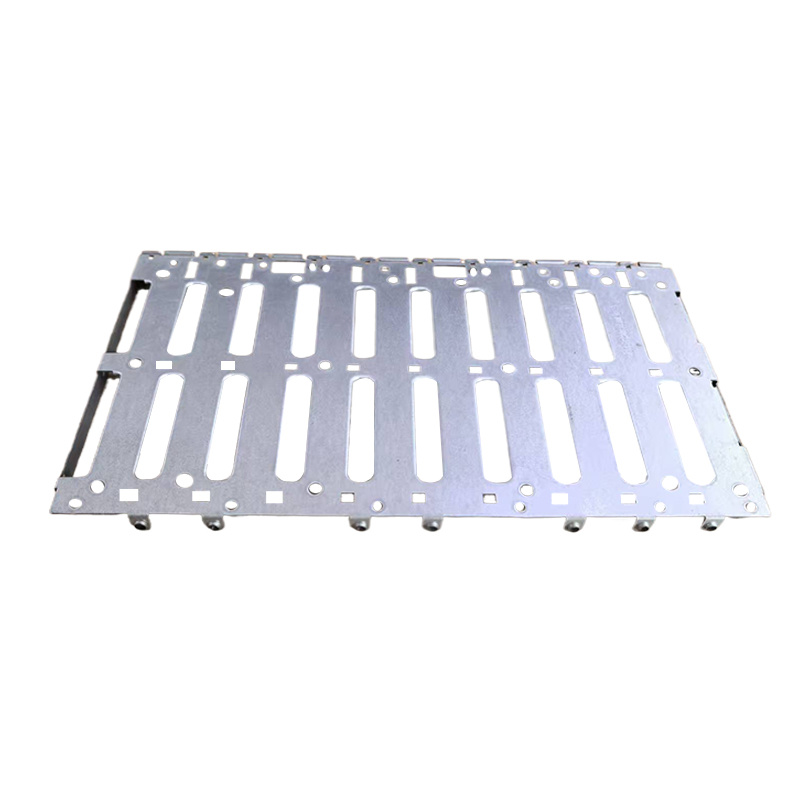

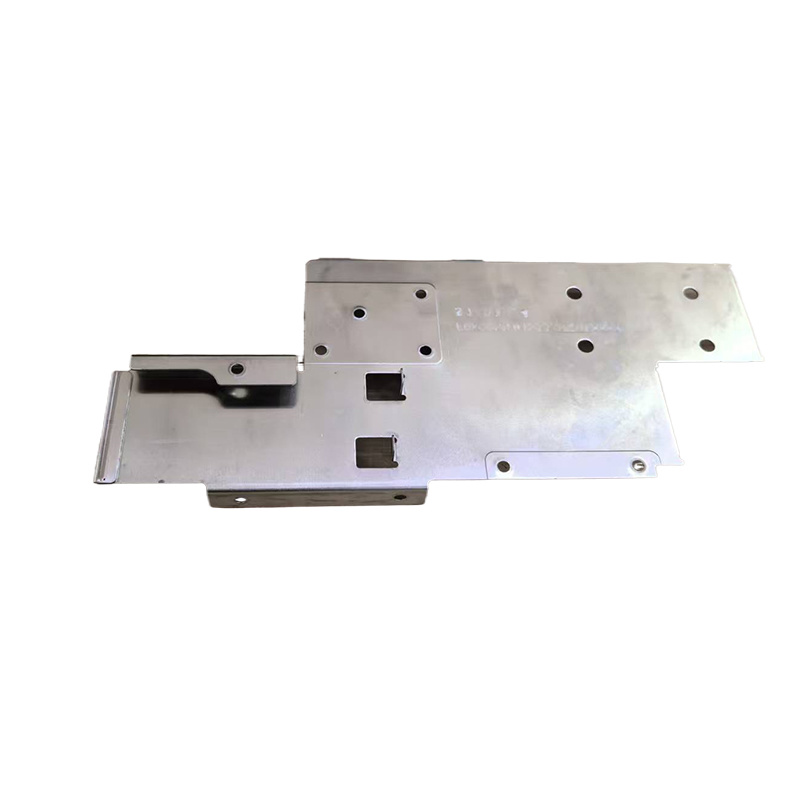

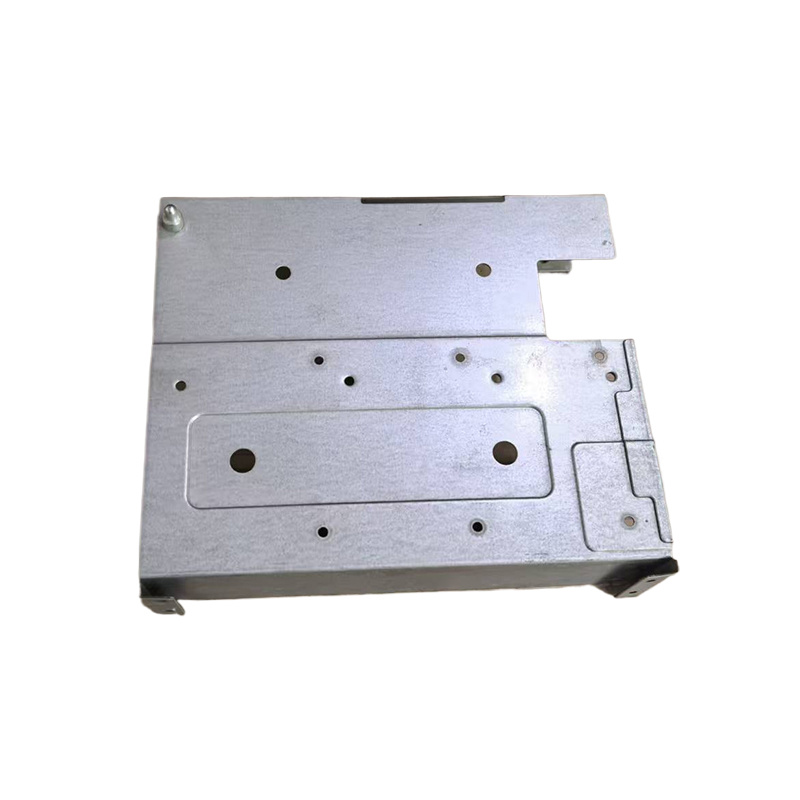

Machined parts

- Commodity name: Machined parts

- Product Description

-

Machined parts refer to components that are processed from raw materials (such as metals, plastics, wood, etc.) into specific shapes, sizes, and precision requirements through mechanical processing methods. Below is a detailed introduction to machined parts:

Common Processing Techniques

◆ Turning Processing

Principle: Turning is one of the most basic and commonly used metal cutting methods, mainly utilizing the rotational motion of the workpiece and the linear or curved motion of the tool on a lathe to change the shape and size of the blank, processing it into parts that meet the requirements.

Application: Commonly used for processing various surfaces of rotating bodies, such as shafts, discs, and sleeves. For example, crankshafts in automobile engines and drive shafts in ordinary machinery are all produced through turning processing.

◆ Milling Processing

Principle: Milling involves using a rotating multi-edge tool to cut the workpiece on a milling machine, where the rotation of the tool is the main motion and the linear movement of the workpiece or tool is the feed motion.

Application: Can process various shapes of surfaces such as flat surfaces, grooves, gears, and threads. For instance, flat milling of mechanical parts, dovetail slot processing of milling machine fixtures, and machining of complex-shaped mold cavities all rely on milling technology.

◆ Drilling Processing

Principle: Drilling is a method of creating holes using a rotating drill bit on a drilling machine. The rotation of the drill bit is the main motion, while its axial movement is the feed motion.

Application: Mainly used for drilling holes; it is a fundamental method for creating various holes, such as mounting holes on box parts and oil holes on shaft parts.

◆ Grinding Processing

Principle: Grinding uses abrasives to perform cutting on the surface of the workpiece. The abrasive particles on the grinding tool perform fine cutting on the workpiece surface at high speeds, achieving the required dimensional accuracy and surface quality.

Application: Typically used in situations where high surface precision and roughness are required, such as crankshaft journals in engines and guide rails in machine tools. After grinding processing, very high dimensional accuracy and smooth surfaces can be obtained.

◆ Boring Processing

Principle: Boring involves using a boring tool on a boring machine to enlarge or refine existing holes in a workpiece. The workpiece or boring tool performs rotational main motion while also performing feed motion.

Application: Particularly suitable for processing holes in complex structures and larger parts such as engine cylinder block holes in automobiles and spindle box holes in large machine tools.

Material Selection

◆ Metal Materials

Steel: Known for its high strength, good toughness, and strong machinability, it is one of the most commonly used materials for machined parts. Depending on carbon content, it can be divided into low-carbon steel, medium-carbon steel, and high-carbon steel. Different types of steel are suitable for different processing requirements and application scenarios. For example, low-carbon steel is often used to manufacture parts that do not require high strength but need good toughness and machinability, such as ordinary bolts and nuts; medium-carbon steel can achieve better strength and toughness after appropriate heat treatment and is commonly used for important mechanical parts like gears and shafts; high-carbon steel has very high strength and hardness and is often used to manufacture tools and springs that require high hardness.

Cast Iron: Known for its good casting performance, wear resistance, and shock absorption properties at relatively low costs. It is commonly used to manufacture complex-shaped parts that require high wear resistance, such as engine cylinder blocks and machine tool beds. Depending on graphite morphology, it can be divided into gray cast iron and ductile cast iron; ductile cast iron has superior mechanical properties compared to gray cast iron and is more widely applied.

Non-ferrous Metals: Such as aluminum, copper, and their alloys have good electrical conductivity, thermal conductivity, corrosion resistance, and machinability. They are commonly used to manufacture parts with special requirements for these properties, such as conductive components in electrical equipment or structural parts in aerospace fields. Aluminum and aluminum alloys have low density and high strength; they are widely used in aerospace and automotive manufacturing; copper and copper alloys have excellent electrical conductivity and thermal conductivity; they are often used to manufacture wires, cables, electronic components, etc.

◆ Non-metal Materials

Plastics: Known for being lightweight, corrosion-resistant, having good insulation properties, and being easy to mold; their application in machining is increasingly widespread. Some engineering plastics like polyamide (nylon), polyoxymethylene (POM), polycarbonate (PC), etc., have high strength and heat resistance suitable for manufacturing various mechanical parts like gears, bearings, casings etc. Compared to metal materials, plastic parts have lower processing costs with higher production efficiency while also providing good shock absorption properties and self-lubrication.

Composite Materials: Made from two or more different materials combined through composite processes; they exhibit superior performance compared to single materials. For example, fiber-reinforced composites combine fibers (like glass fibers or carbon fibers) with matrix materials (like resins) to achieve characteristics like high strength, high modulus, low density; they are commonly used to manufacture high-performance structural parts like aircraft wings or car bodies. During machining processes involving composite materials, it is necessary to select appropriate processing techniques and tools based on their composition and performance characteristics.

Advantages and Limitations

◆ Advantages

High Precision: Through precise processing equipment and process control, very high dimensional accuracy and shape precision can be achieved to meet various manufacturing requirements for precision mechanical parts. For instance, some critical components in aerospace require precision levels reaching micrometers or even nanometers; these can be accurately manufactured through machining.

Ability to Process Complex Shapes: Capable of producing various complex-shaped parts regardless of whether they have concave structures or thin-walled structures or special curved surfaces; this can be achieved through combinations of different processing techniques. For example, various cavities or cores in mold manufacturing are processed through multiple machining techniques resulting in diverse complex shapes that meet different product forming needs.

Wide Applicability: Can process various materials including metals, non-metal materials as well as composite materials covering almost all engineering materials; thus its application fields are very broad ranging from aerospace manufacturing to mechanical equipment to electronic information medical devices among many industries relying on machined parts.

High production efficiency: With the continuous development of automated processing technology, the production efficiency of machining has greatly improved. By using CNC processing equipment and automated production lines, continuous processing of multiple operations can be achieved, reducing manual intervention and increasing processing speed and the stability of product quality. For example, in the mass production of automotive parts, an automated machining production line can quickly and efficiently produce a large number of standard-compliant parts.

◆ Limitations

High cost of equipment and tools: Machining requires various specialized processing equipment, such as lathes, milling machines, drilling machines, grinding machines, etc., as well as supporting tools, fixtures, and measuring instruments. The procurement costs of these equipment and tools are relatively high, especially for some high-precision and high-performance processing equipment, which are even more expensive. For some small enterprises or units with lower processing demands, the investment cost may be significant and could limit their development.

Waste generated during processing: During machining, a certain amount of waste is produced because excess material must be cut away from the raw materials to obtain the desired shape and size of parts. This not only leads to material waste but also increases processing costs and environmental burdens. This is particularly evident in the processing of valuable materials.

High skill requirements for operators: Machining operations require certain professional knowledge and skills. Operators need to be familiar with the performance and operation methods of various processing equipment, as well as master processing technology and programming techniques. Operators lacking experience or skills may lead to quality issues in machining, such as dimensional deviations or non-compliance with surface roughness standards, and may even cause equipment accidents and safety incidents.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.