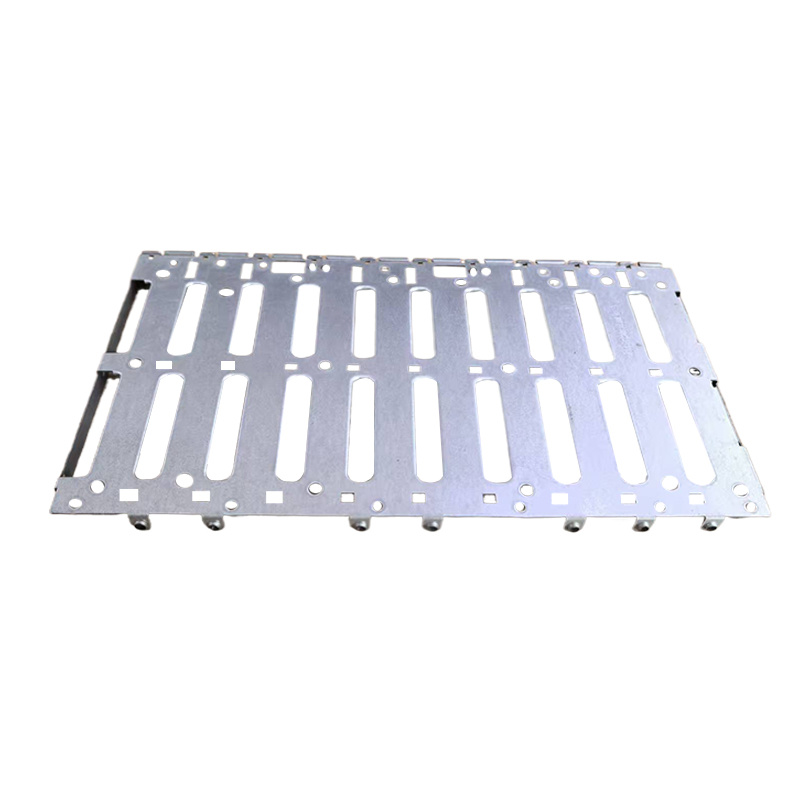

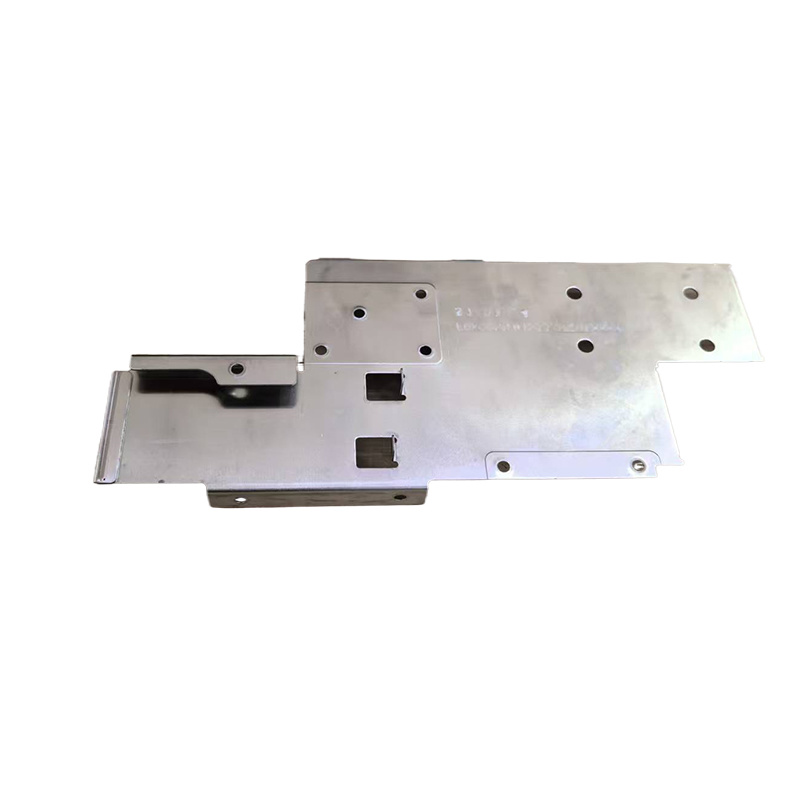

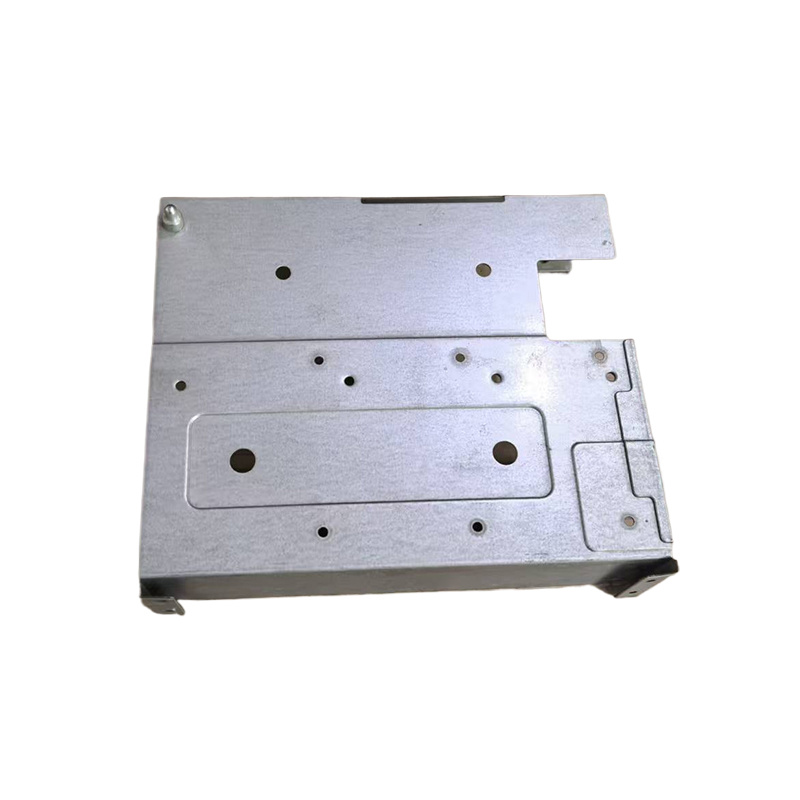

Stamping parts

- Commodity name: Stamping parts

- Product Description

-

Stamping parts rely on pressure machines and molds to apply external force to materials such as sheets, strips, pipes, and profiles, causing them to undergo plastic deformation or separation, thereby obtaining the desired shape and size of the workpiece.

Characteristics of Stamping Parts

◆ High Production Efficiency

The stamping production process mainly relies on molds and stamping equipment, allowing one or more stamping parts to be obtained in a single stamping stroke, making it easy to operate and fast in production speed.

For example, in the production of automotive body covers, large stamping equipment and molds can produce several or even dozens of pieces per minute, quickly meeting the demands of mass production.

◆ Stable Quality

The dimensional accuracy and shape accuracy of stamping parts are mainly guaranteed by the molds. As long as the mold precision is high, the structure is reasonable, and the stamping equipment performs well, it can stably produce parts with consistent dimensions and precise shapes.

For example, some precision stamping parts in electronic devices can control dimensional tolerances within a very small range, ensuring the overall performance and reliability of the electronic devices.

◆ High Material Utilization Rate

Stamping is a method of processing with little to no cutting. During the stamping process, the deformation of the material is mainly plastic deformation, resulting in relatively little waste and a high material utilization rate.

Taking the manufacture of metal gaskets as an example, through reasonable layout design, the material utilization rate can exceed 80%, effectively saving costs and resources.

◆ Capable of Processing Complex-Shaped Parts

With the help of advanced mold manufacturing technology, it is possible to design and manufacture various complex-shaped molds, thus stamping out parts with complex shapes.

For example, parts with complex structures such as thin walls, reinforcing ribs, and undercuts can be easily manufactured using stamping processes.

Production Process of Stamping Parts

◆ Cutting

Cutting is a stamping process that uses molds to separate the sheet along a certain contour shape, including blanking and punching.

Blanking is the process of punching out the required shape from the sheet, where the punched-out part is the finished product and the surrounding area is waste; punching is the process of punching holes of the required shape in the sheet, where the punched-out part is waste and the surrounding area is the finished product.

◆ Bending

Bending is a stamping process that bends sheets, profiles, or pipes to a certain angle and curvature.

By using bending molds and stamping equipment, the workpiece undergoes plastic deformation under the action of bending moments, forming the desired bending shape, commonly used to manufacture various bent components such as brackets and hooks.

◆ Stretching

Stretching is a stamping process that pulls flat blank into a die under the action of a convex die to form open hollow parts.

During the stretching process, the material is subjected to stretching forces, resulting in plastic flow, gradually forming various hollow shapes such as cylindrical, spherical, and box-shaped parts, like beverage cans and metal lampshades.

Application Fields of Stamping Parts

◆ Automotive Industry

Many key components such as automotive bodies, engine parts, and chassis parts extensively use stamping parts.

For example, the coverage parts of the body, longitudinal and transverse beams of the frame, and the oil pan of the engine, the application ratio of stamping parts in automobile manufacturing exceeds 60%.

◆ Electronic Equipment Manufacturing Industry

The shells, circuit boards, and connectors of electronic devices are usually produced using stamping processes.

For example, the metal shells of mobile phones and the main cases of computers, these stamping parts not only have precise dimensions and shapes but also meet the special performance requirements of electronic devices such as electromagnetic shielding.

◆ Machinery Manufacturing Industry

Various mechanical parts, such as gears, bushings, and flanges, can be manufactured through stamping processes.

For some small mechanical parts, stamping processing can improve production efficiency, reduce costs, while ensuring the quality and performance of the parts.

◆ Daily Necessities Industry

From household items to office supplies, stamping parts are everywhere.

Common stamping products include the frames of metal tables and chairs, components of filing cabinets, scissors, and other tools. The stamping process provides a rich variety of cost-effective products for daily life.

Quality Inspection of Stamping Parts

◆ Appearance Inspection

Mainly checks the surface quality of stamping parts, including whether there are defects such as cracks, scratches, wrinkles, and deformations.

Through visual inspection or using tools such as magnifying glasses, a comprehensive inspection of the appearance of stamping parts is conducted to ensure that their surface quality meets the requirements.

◆ Dimensional Inspection

Checks whether the dimensional accuracy of stamping parts meets the requirements of the design drawings.

Using measuring tools such as calipers, micrometers, and coordinate measuring machines to measure the key dimensions of stamping parts, ensuring that their dimensional deviations are within acceptable ranges.

◆ Performance Testing

Conduct corresponding performance tests based on the specific usage requirements of stamping parts, such as strength tests, hardness tests, and toughness tests.

Using professional testing equipment and methods to simulate the working conditions of stamping parts in actual use, verifying whether their performance meets the requirements.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.