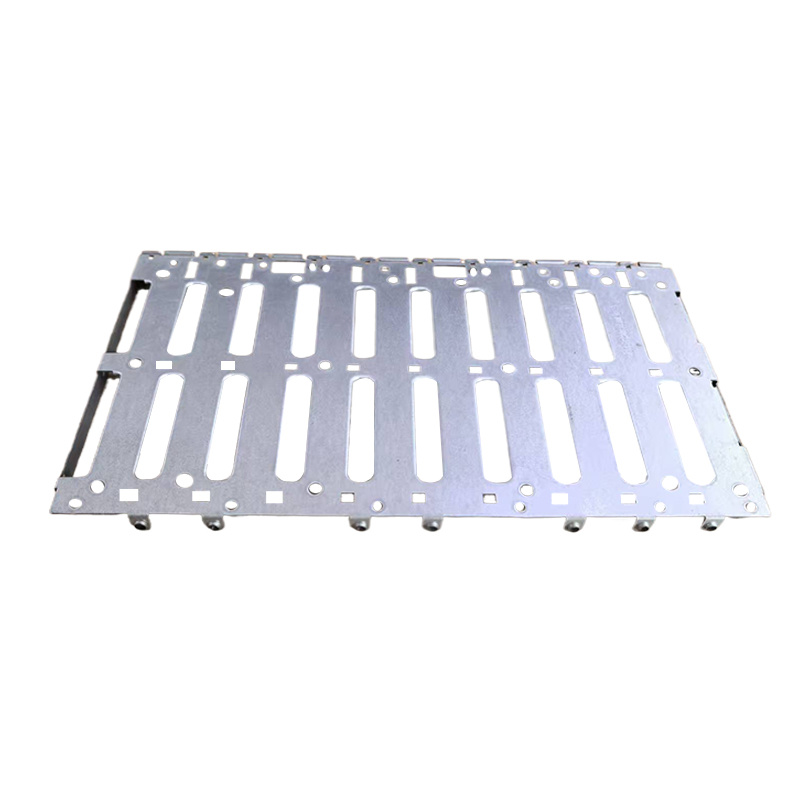

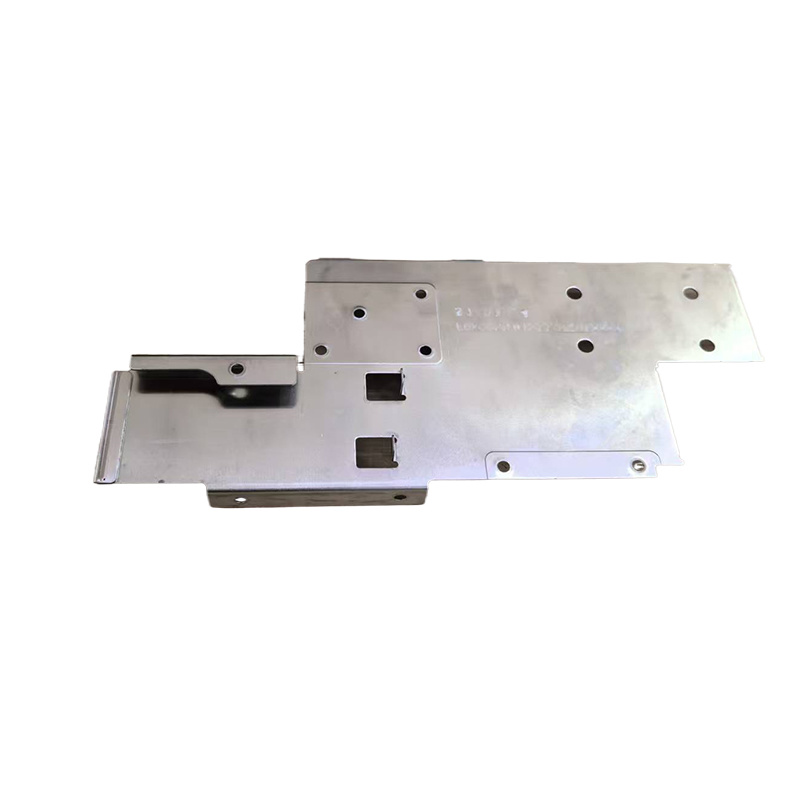

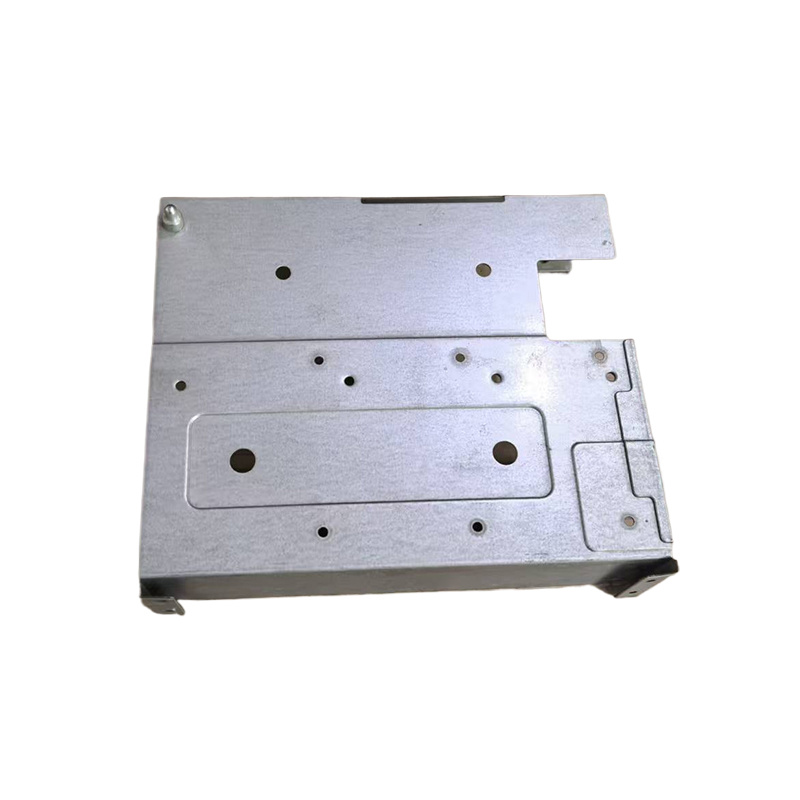

Side area control bracket

- Commodity name: Side area control bracket

- Product Description

-

Definition and Purpose

The side area control bracket is a device used to control and support specific side areas. Its main purpose is to achieve effective management of lateral components or work areas through precise positioning and stable support in various devices or structures. For example, in industrial automation production lines, the side area control bracket can be used to fix and adjust lateral sensors, actuators, and other equipment, ensuring they operate in the correct position, thereby ensuring the efficient operation of the production line. In the construction field, it can be used to support decorative components and shading facilities on the sides of buildings, allowing these components to be securely installed and perform their functions.

Structural Composition

Bracket Body: This is the main structural part of the side area control bracket, usually made of metal materials (such as steel or aluminum alloy). The shape and size of the bracket body are determined by specific application scenarios and load requirements. It may be a simple column structure or a complex shape with multiple branches and connections. For example, in a bracket used to support large machinery side components, the bracket body may be a frame structure welded from robust steel beams to provide sufficient strength and stability.

Connecting Components: These include various types of connectors such as bolts, nuts, and pins, used to connect the bracket body with the supported components or other structures. These connectors need to have sufficient strength and reliability to ensure tightness and stability of the connection. For example, in automobile manufacturing, the side area control bracket is connected to components on the side of the vehicle body through specially designed bolts that must meet vibration and load requirements during vehicle operation.

Adjustment Device: To adapt to different working environments and needs, side area control brackets are usually equipped with adjustment devices. The adjustment device can be a screw-type adjustment rod that changes the height, angle, or position of the bracket by rotating it. It can also be a sliding adjustment mechanism that achieves fine-tuning of position through sliding components. For example, in stage equipment, the adjustment device on the side area control bracket can be used to adjust the angle and height of lighting equipment to meet lighting effect requirements for different performance scenarios.

Fixed Base: The fixed base is the part where the bracket contacts the installation plane (such as ground, wall, or equipment platform). Its function is to securely fix the bracket in place, preventing movement during operation. The shape of the fixed base can be circular, square, or other shapes suitable for installation surfaces. In some cases where installation on uneven ground is required, the fixed base may also be equipped with adjustable foot pads to ensure stability.

Classification Methods

Classification by Application Field:

Industrial Side Area Control Bracket: Mainly used in industrial production environments such as factory workshops, mines, chemical equipment, etc. This type of bracket usually needs to have high strength, precision, and corrosion resistance to adapt to harsh environments and high-precision work requirements in industrial production. For example, in an electronic chip manufacturing workshop, side area control brackets are used to fix and adjust lateral components of chip production equipment that must meet special requirements such as dust-free and anti-static.

Construction Side Area Control Bracket: Used during building construction, renovation, and maintenance processes. It can support decorative materials on building facades, curtain wall systems, shading panels, etc. Construction brackets need to consider factors such as overall architectural style, load-bearing requirements, and service life. For example, in curtain wall installation for high-rise buildings, side area control brackets must not only provide sufficient support but also consider wind resistance and seismic performance.

Transportation Side Area Control Bracket: Used in vehicles such as cars, trains, ships, etc. This type of bracket is mainly used to fix and support equipment on the sides of vehicles or ships such as luggage racks and guardrails. For example, inside a car, side area control brackets are used to install side seat armrests and airbag modules that need to meet safety and comfort requirements during vehicle operation.

Classification by Structural Form:

Cantilever Side Area Control Bracket: This type of bracket has a cantilever structure fixed at one end on a support point while supporting or controlling components in the side area at the other end. Cantilever brackets can flexibly adjust support positions but have relatively limited load capacity; they are suitable for situations with smaller loads. For example, on the side of a laboratory fume hood, cantilever brackets can be used to suspend small experimental instruments.

Frame Side Area Control Bracket: Formed by multiple rods connected through welding or bolts into a frame structure. Frame brackets have high strength and stability capable of bearing larger loads. They are typically used in situations requiring extensive support or high structural stability requirements. For example, in supporting maintenance platforms on large machinery equipment sides, frame brackets can provide a stable working platform.

Combination Side Area Control Bracket: A bracket that combines various structural forms together. It integrates advantages from different structures allowing flexible configuration based on specific application needs. For example, in some complex industrial automation equipment, combination brackets can simultaneously use cantilever structures and frame structures for effective support of lateral components with different positions and load requirements.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.