Frame installation plate

- Commodity name: Frame installation plate

- Product Description

-

Definition and Purpose

The frame mounting plate is a metal plate used to install various components onto the frame. The frame mounting plate plays a crucial role in the manufacturing and assembly processes of vehicles such as cars, motorcycles, bicycles, and some industrial vehicles. It provides a stable connection interface, allowing components such as engines, suspension systems, body shells, and seats to be securely mounted on the frame, ensuring the stability and safety of the vehicle during operation.

Structural Composition

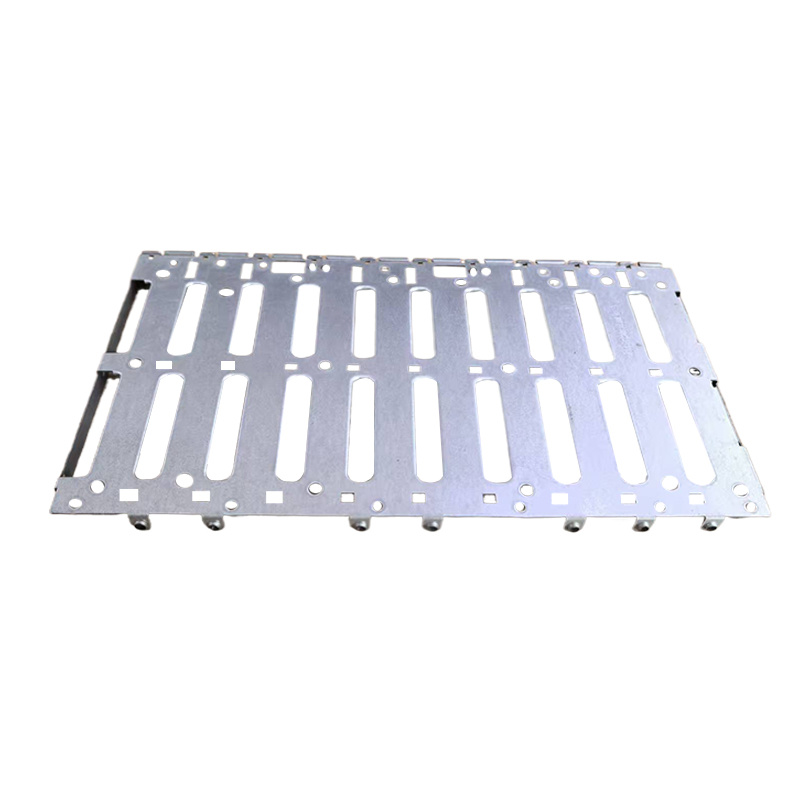

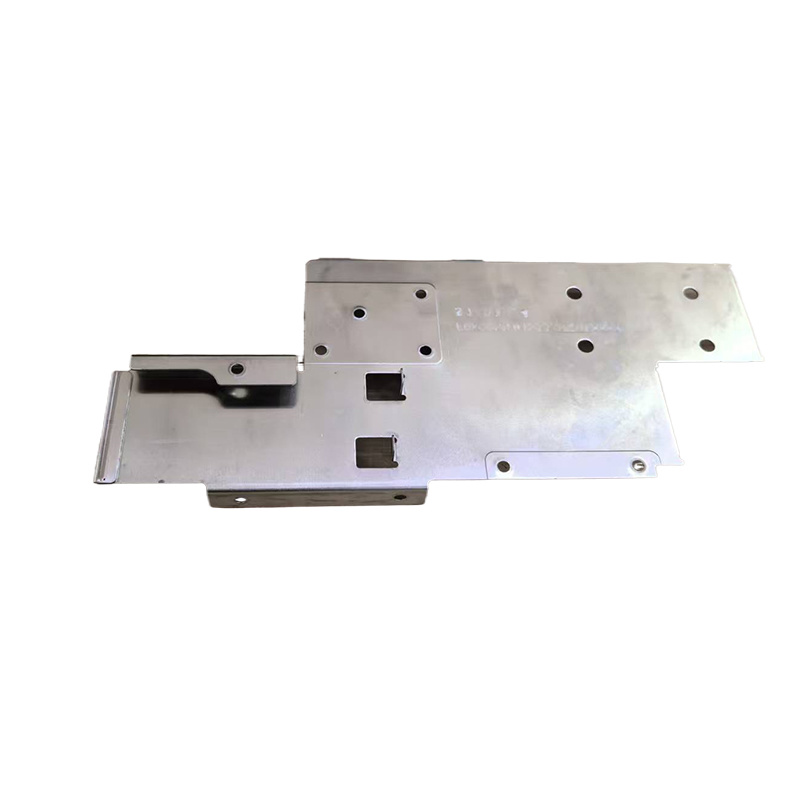

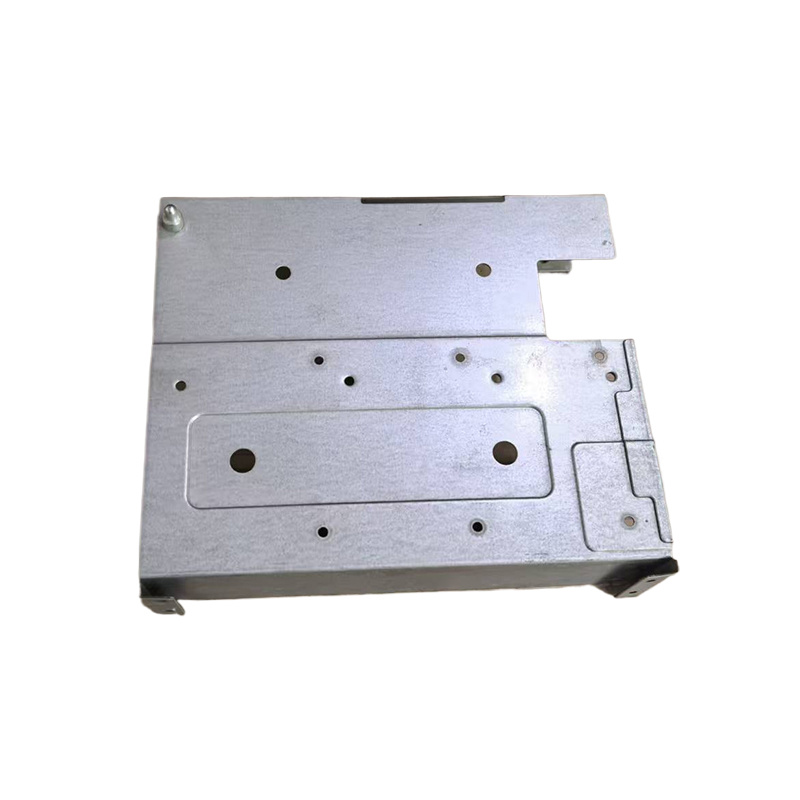

Plate Body: The main part of the frame mounting plate, usually a metal plate whose shape and size are determined by specific installation requirements and the structure of the frame. The material of the plate body is generally high-strength steel or aluminum alloy. Steel has high strength and toughness, capable of withstanding large loads, commonly used for heavy-duty vehicles and industrial vehicle frame mounting plates; aluminum alloy is lighter in weight, making it suitable for situations with strict weight requirements (such as high-performance cars and motorcycles). The surface of the plate body may be treated, such as galvanized or painted, to enhance its corrosion resistance.

Mounting Holes: The frame mounting plate has many mounting holes, with their positions, sizes, and shapes designed according to the connection requirements of the components to be installed. Mounting holes can be round, square, or other special shapes. For components that require high-precision installation, the positional accuracy of the mounting holes is very high, often achieved through precise processing methods such as CNC machining during manufacturing.

Reinforcement Ribs: To enhance the strength and rigidity of the frame mounting plate, reinforcement ribs may be designed on the plate body. Reinforcement ribs can be raised linear structures or rib-like structures. They effectively disperse the stress generated during component installation and prevent deformation of the mounting plate under large loads. For example, on an automotive engine mounting plate, due to the engine's heavy weight and vibrations during operation, the design of reinforcement ribs ensures that the mounting plate can withstand these loads without damage.

Connection Edges: The edge part of the frame mounting plate is used for connection with the frame. The connection edges may be flat and connected to the frame through welding or bolting; they may also have folded or rolled structures that increase the strength of the connection edges and better fit the shape of the frame during installation, improving sealing and stability.

Classification Methods

Classified by Vehicle Type:

Automotive Frame Mounting Plates: Automotive frame mounting plates have different designs based on vehicle types (sedans, SUVs, trucks, etc.) and purposes (passenger use, commercial use, off-road use). Sedan frame mounting plates typically consider comfort and space utilization; their shapes are more complex for installing interior components like seats; SUV frame mounting plates may focus more on off-road performance requiring sufficient strength to install large suspension systems and four-wheel drive components; truck frame mounting plates are mainly used for carrying cargo and installing large power systems and cabins, requiring larger sizes and higher strength.

Motorcycle Frame Mounting Plates: Motorcycle frame mounting plates are relatively small and compact. Depending on motorcycle styles (street bikes, sport bikes, off-road motorcycles), their designs vary. For example, off-road motorcycle frame mounting plates need to consider impact resistance in complex terrains for installing engines, fuel tanks, suspension systems, etc., while being able to adapt to various forces generated during jumps and bumps.

Bicycle Frame Mounting Plates: Mainly used for installing bicycle components such as gear shifters, brake devices, racks, etc. Bicycle frame mounting plates are smaller in size and typically made from lightweight materials but still require certain precision and strength to ensure that all bicycle components function properly and safely.

Classified by Installed Components:

Engine Mounting Plates: Used for installing vehicle engines; their structure needs to consider factors like engine weight, vibration characteristics, and power output direction. Engine mounting plates usually have specialized shock-absorbing devices and positioning structures to reduce engine vibrations' impact on the vehicle and ensure correct engine positioning on the frame.

Suspension Mounting Plates: Used to connect a vehicle's suspension system including shock absorbers, springs, control arms, etc. The design of suspension mounting plates must consider vehicle stability and comfort while being able to withstand various impacts from road surfaces during driving and effectively transmit these forces to the frame.

Body Mounting Plates: Used for installing a vehicle's body shell or covering parts. The shape and surface quality of body mounting plates significantly affect a vehicle's appearance while also needing to provide sufficient connection strength to ensure that body components do not loosen or produce noise during vehicle operation.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.