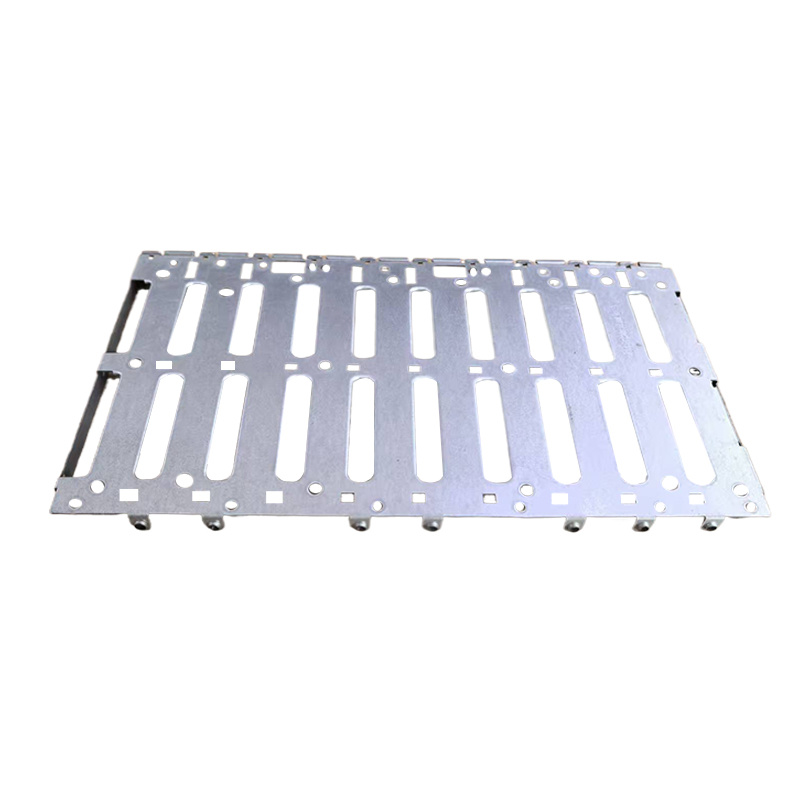

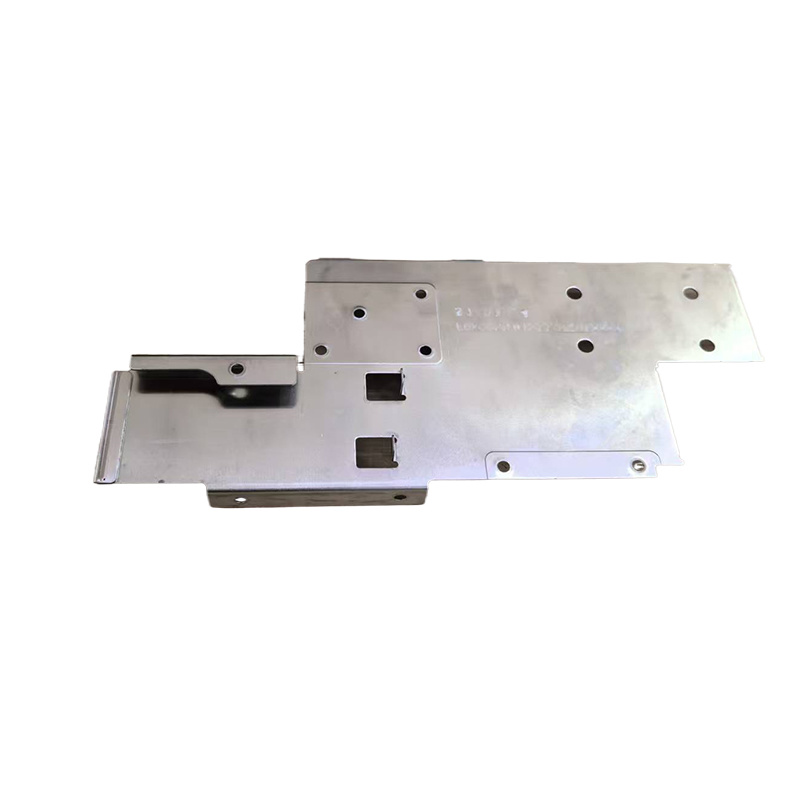

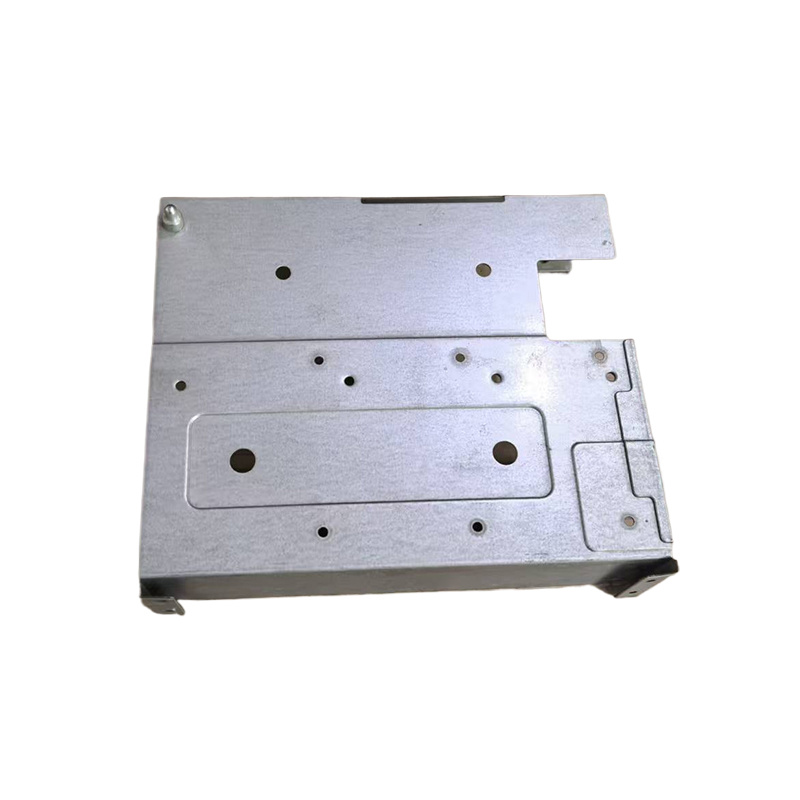

Sensor bracket

- Commodity name: Sensor bracket

- Product Description

-

Definition and Purpose

The sensor bracket is a device specifically designed for installing and securing sensors, aimed at providing a stable and suitable installation position for the sensors, ensuring that they can accurately perceive and measure target physical quantities (such as temperature, pressure, displacement, speed, etc.), thereby reliably performing their monitoring and control functions. In various fields such as industrial automation, automotive manufacturing, environmental monitoring, and smart homes, sensor brackets are indispensable components that ensure the normal operation of sensors.

Structural Composition

Bracket Body:

Typically made of metal (such as stainless steel, aluminum alloy, carbon steel, etc.) or high-strength plastic. Metal brackets have high strength and stability, capable of adapting to complex and harsh working environments, commonly used in industrial settings, such as brackets for installing pressure sensors and vibration sensors in factory workshops; plastic brackets are relatively lightweight, cost-effective, and have certain insulation properties, often used in home and office environments where conditions are milder and weight-sensitive, such as some humidity and temperature sensor brackets in smart home systems.

They come in various shapes, commonly cylindrical, plate-shaped, L-shaped, U-shaped, frame-type, etc., with the specific shape depending on the characteristics of the sensor's appearance and the spatial layout and requirements of the installation environment. For example, when installing a temperature sensor in a car engine compartment, an L-shaped bracket may be used to precisely position the sensor next to the critical area where temperature needs to be monitored while securely fixing it to the corresponding structure in the compartment using its angled structure.

Connecting Components:

Including various forms such as bolts, nuts, clips, clamps, magnetic attachments, etc. The bolt and nut connection method is firm and reliable, able to withstand significant external forces and vibrations, suitable for sensors installed in industrial automation production lines that require long-term stable installation with high safety requirements; clips and clamps allow for quick and easy connection operations for rapid installation and removal of sensors, commonly used in situations where sensors need to be frequently replaced or adjusted, such as in some environmental monitoring stations where air quality sensors can be easily maintained; magnetic connections use magnetic attraction to secure sensors; this method is simple and does not require drilling or other operations, often used in situations where the installation surface will not be damaged and where fixing strength is not highly required, such as attaching small sensors to metal surfaces in some smart home devices.

The size and specifications of connecting components need to match the bracket body and the sensor's installation interface to ensure a tight and stable connection.

Adjustment Device (partially equipped):

Some sensor brackets are equipped with adjustment devices to meet different installation angle, height or position requirements. Common adjustment devices include rotatable joints, extendable rods, sliding slots, etc. Rotatable joints allow the sensor to flexibly change angles within a certain range for aligning with monitoring targets; for example, in optical sensor brackets, the light angle of the sensor can be precisely adjusted through a rotating joint; extendable rods can adjust the height above ground or protruding length of the sensor according to actual conditions, suitable for situations like level sensors that need flexible installation positions based on container sizes; sliding slots allow the sensor to slide horizontally or vertically on the bracket to find the best monitoring position; for instance, when installing position sensors on automated production lines, sliding slots can fine-tune the sensor's position for precise location detection.

The design of adjustment devices must ensure both flexibility in adjustment and stability after adjustment is completed so that it will not easily change its set position and angle due to external vibrations or other interference factors.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.