Powertrain bracket

- Commodity name: Powertrain bracket

- Product Description

-

Definition and Purpose

The powertrain bracket is a key component in the automotive chassis system, primarily used to support and secure the vehicle's powertrain, including the engine, transmission, driveshaft, and other components. It serves as a connection between the powertrain and the vehicle body or frame, transmitting the weight of the powertrain and various forces generated during operation (such as engine torque and vibrations) to ensure the stability of the powertrain's position while the vehicle is in motion. It also provides a relatively stable mounting base for the normal operation of the powertrain.

Structural Composition

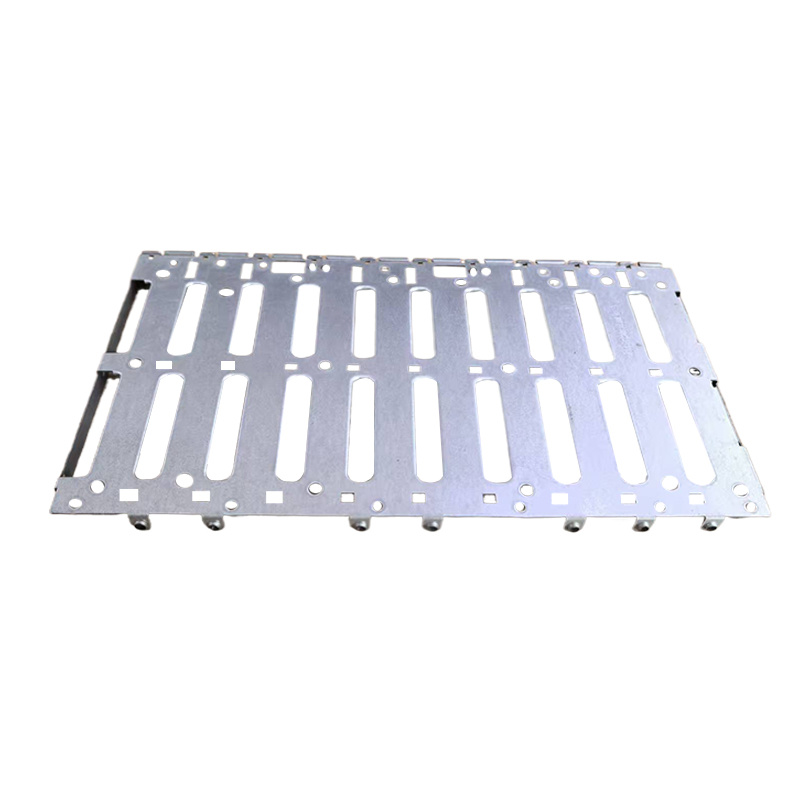

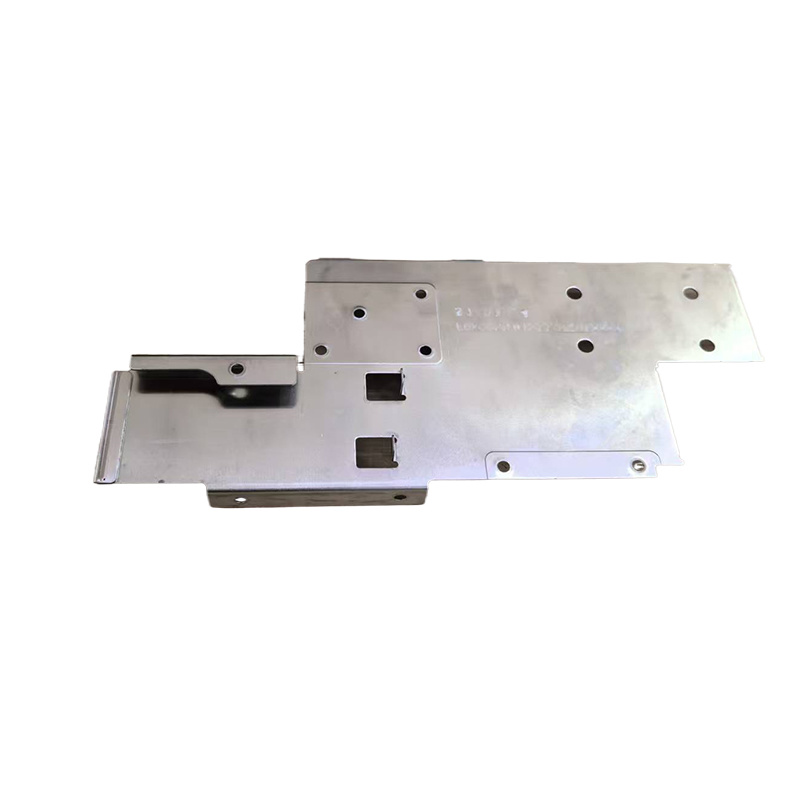

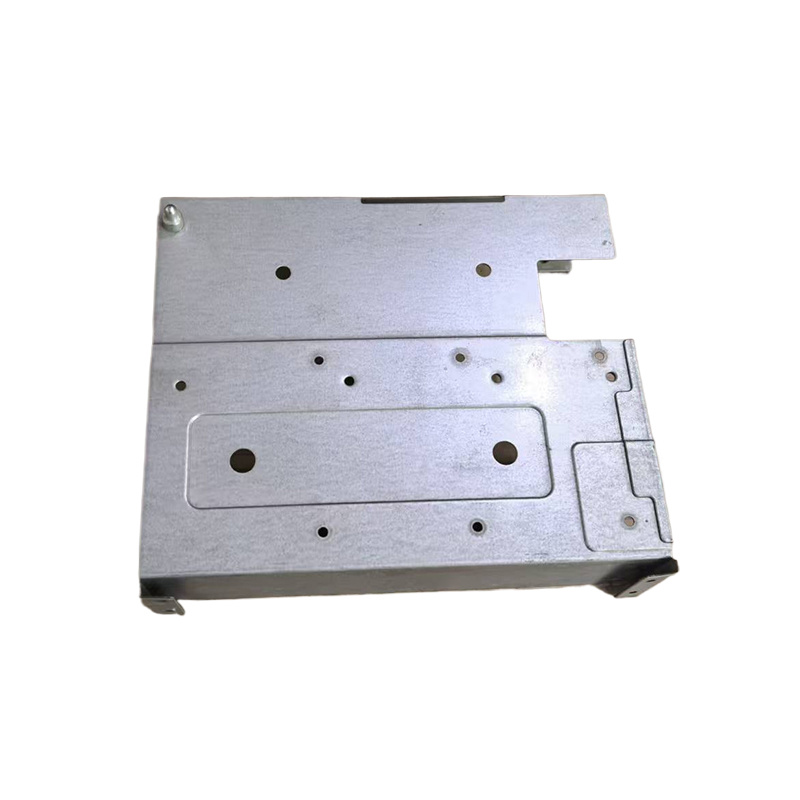

Bracket Body:

Typically made from high-strength metal materials, such as high-strength steel or aluminum alloy. High-strength steel has high strength and toughness, capable of withstanding large loads, making it a common material for traditional fuel vehicle powertrain brackets; aluminum alloy is used in some models that require lightweight vehicles (such as new energy vehicles) due to its lighter weight. The shape of the bracket body is relatively complex and is generally designed according to the shape and installation requirements of the powertrain. It may include multiple flat surfaces, curved surfaces, and reinforcing ribs to provide sufficient support area and structural strength. For example, the bracket body may have a large flat surface for placing the engine, surrounded by upwardly curved edges or reinforcing ribs to prevent vertical displacement of the engine.

Mounting Brackets and Connection Components:

The powertrain bracket has various mounting brackets used to connect different components of the powertrain. The position and shape of these brackets are precisely matched to the mounting points of the powertrain components. For example, engine mounting brackets are usually located at specific positions on the bracket body and are connected to the engine's bracket via bolts or rubber bushings to reduce engine vibration transmission to the vehicle body. Connection components mainly include bolts, nuts, and some special connectors such as rubber bushings and hydraulic bushings. Rubber bushings and hydraulic bushings can act as buffers and dampers, effectively reducing vibration transmission to the vehicle body during engine operation, thereby improving ride comfort.

Reinforcement Structure:

To enhance the overall strength and rigidity of the bracket, reinforcement structures are typically designed. Reinforcement structures can be ribs, reinforcing ribs, or additional support structures. Ribs are thin plate-like structures that protrude from the surface of the bracket body, increasing strength in specific directions; reinforcing ribs are line-shaped protrusions that help distribute stress more evenly when the bracket bears loads. For example, reinforcing ribs may be arranged at the edges of the bracket or in areas that bear larger loads to prevent deformation under the weight and torque of the powertrain.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.