Fixed frame

- Commodity name: Fixed frame

- Product Description

-

Definition and Purpose

A fixture is a device used to fix, support, and position objects, aimed at ensuring that the object maintains a stable position and posture under specific environments and conditions. In the automotive field, fixtures are widely used in various systems, such as engine mounts that secure the engine to keep it stable during vehicle operation, preventing vibrations and displacements from affecting power transmission and vehicle performance; electronic device mounts ensure that various electronic components (such as onboard computers, sensors, etc.) in the car are accurately installed to prevent damage or signal transmission issues due to shaking. In industrial production, fixtures are also used to secure various mechanical parts for processing, assembly, or transportation.

Structural Composition

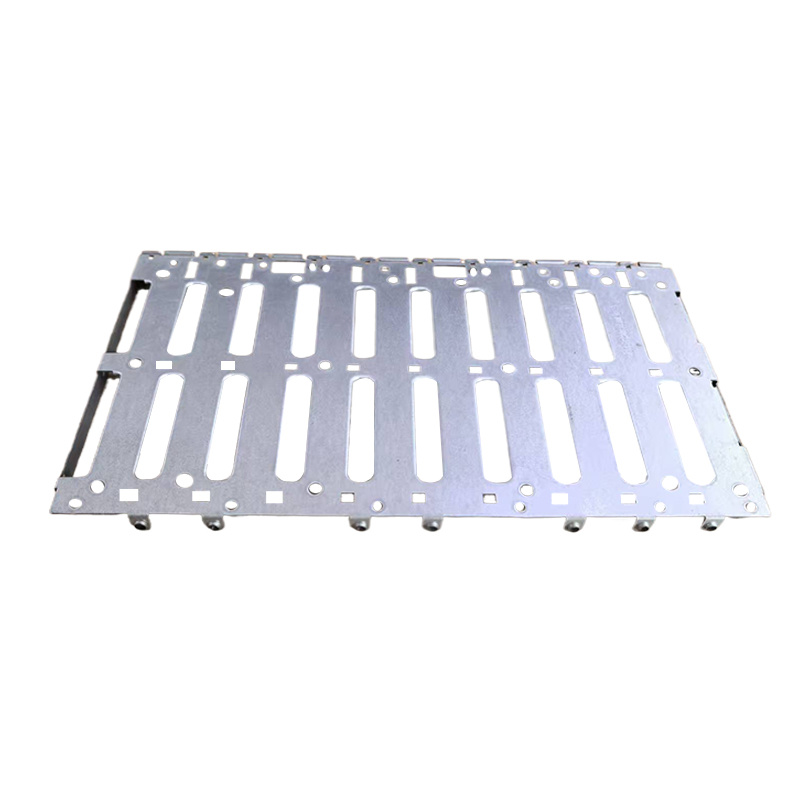

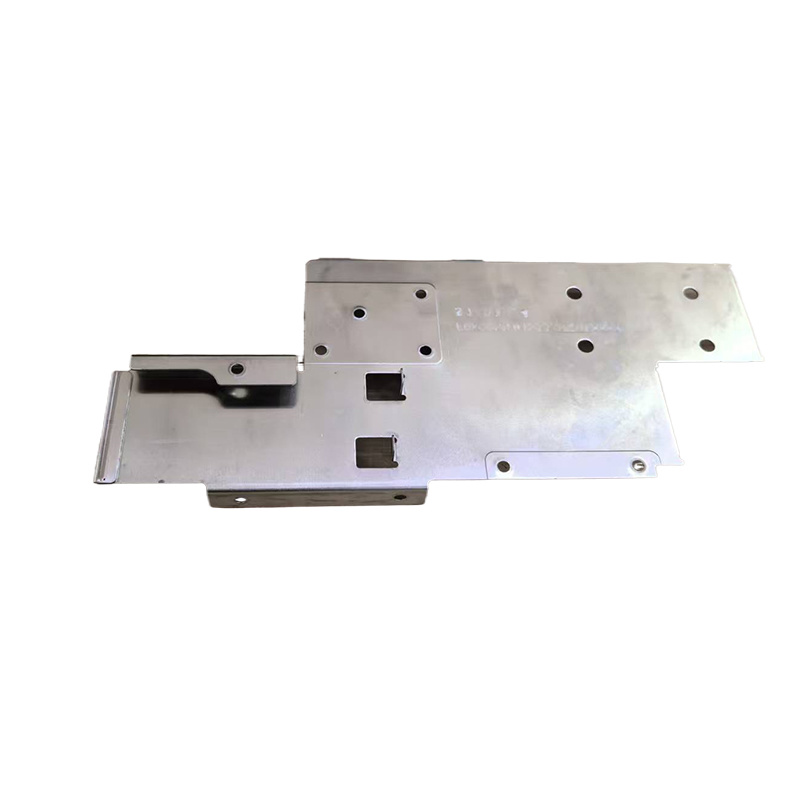

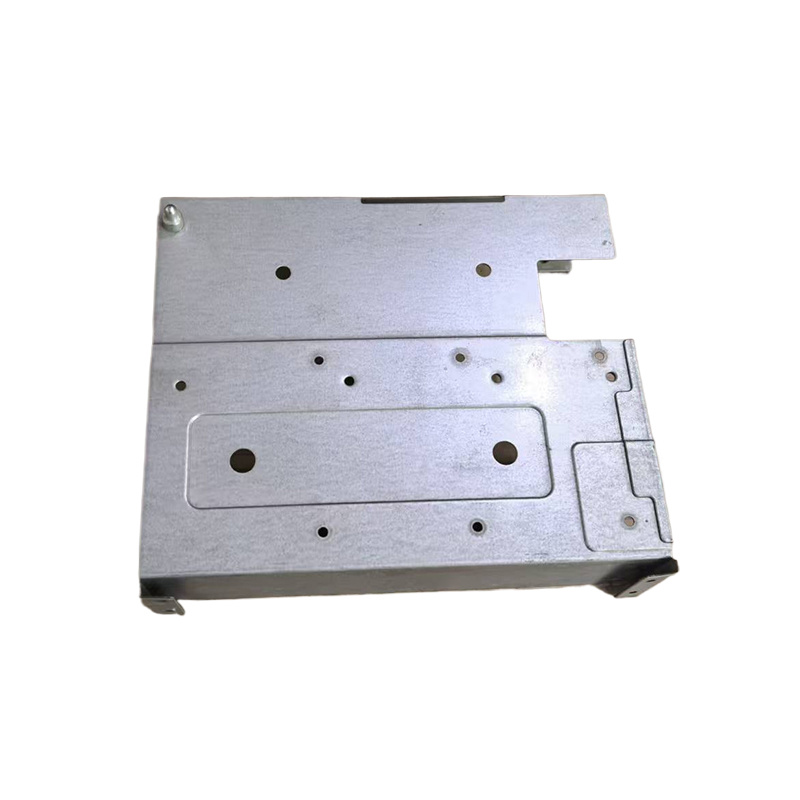

- Main Body of the Fixture

- Shape and Design: The shape of the main body of the fixture varies according to its purpose and the shape of the object being fixed. It can be a simple flat structure for securing flat objects; or it can have multiple branches, curves, or angles in complex shapes to accommodate irregularly shaped objects. For example, when securing a car engine, the main body of the fixture may be a metal frame with multiple protrusions and recesses designed to match the contours of the engine's bottom and sides for better fit and support.

- Material Selection: The materials are usually metal (such as steel, aluminum) or high-strength plastic. Metal fixtures have high strength and good toughness, capable of bearing large weights and external forces, commonly used for securing heavier objects like large motor mounts in industrial equipment; aluminum alloy fixtures not only have certain strength but also lighter weight, making them more commonly used in automotive parts fixation and some weight-sensitive equipment; high-strength plastic fixtures are cost-effective, corrosion-resistant, and advantageous in some insulating applications, such as electronic device mounts.

- Connecting Components

- Bolts and Nuts: This is the most common method of connection. Bolts pass through mounting holes on the fixture and the object being fixed, then tightened with nuts. The specifications of bolts (such as diameter, length, pitch, etc.) are chosen based on the load requirements of the fixture and the thickness of the object being fixed. In automotive engine mounts, high-strength bolts and nuts are typically used with strict torque requirements to ensure secure fixation of the engine.

- Clips and Slots: The clip-and-slot connection method is simple and quick to operate, facilitating installation and disassembly. This connection method is suitable for situations where high fixation strength is not particularly required and frequent installation and disassembly are needed. For example, in automotive interior component fixtures, some small plastic decorative parts can be secured to the vehicle frame using clips and slots.

- Welding (in some cases): For some permanent fixations or situations requiring extremely high connection strength, welding is used to connect the fixture with the object being fixed or its mounting base. Welding can provide very high connection strength but makes disassembly and adjustment difficult once completed. In industrial production, some large metal structure fixtures may use welding to connect with the equipment's base frame.

- Buffering and Shock Absorbing Components (some have)

- Rubber Pads: Rubber pads are common buffering and shock-absorbing components. They are usually installed between the fixture and the object being fixed; when the object experiences vibrations or impacts, rubber pads can absorb and disperse energy, reducing vibration transmission to the fixture and surrounding environment. In automotive engine mounts, rubber pads can effectively reduce engine vibrations' impact on the vehicle body, enhancing ride comfort.

- Springs (rare cases): In some special fixture designs, such as those for precision instruments sensitive to vibrations, springs may be used as shock-absorbing components. Springs can stretch or compress according to vibration frequency and amplitude, converting vibrational energy into elastic potential energy to protect instruments from vibration damage.

- Main Body of the Fixture

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.