Stainless steel spring

- Commodity name: Stainless steel spring

- Product Description

-

Stainless steel spring plates are elastic sheet-like components made from stainless steel materials, playing an important role in many fields. Here is a detailed introduction about them:

Characteristics

◆ Good elasticity

Stainless steel spring plates can undergo elastic deformation when subjected to certain external forces, and can quickly return to their original shape and size once the external force is removed. This good elasticity allows them to play a key role in various devices that require elastic force.

For example, in the internal structure of some mechanical keys, stainless steel spring plates are installed beneath the keys. When the key is pressed, the spring plate deforms under pressure, and when the finger is released, the spring plate relies on its own elasticity to return to its original state, thus achieving the rebound function of the key and providing users with a good tactile experience.

◆ Corrosion resistance

The stainless steel material itself has excellent corrosion resistance, which allows stainless steel spring plates to maintain good performance and appearance even in harsh working environments or when in prolonged contact with corrosive media, extending their service life.

For instance, in outdoor electronic devices, even when exposed to humid air, rainwater, or various chemicals for a long time, stainless steel spring plates are not easily rusted or corroded, ensuring the normal operation and reliability of electronic devices.

◆ High strength

Stainless steel spring plates possess high strength and can withstand significant external forces without undergoing plastic deformation or damage. This makes them perform excellently in applications that require high strength.

Taking the valve spring plates of automotive engines as an example, during high-speed operation of the engine, the valve spring plates need to withstand frequent impacts and pressures. The high strength of stainless steel spring plates ensures their stable operation under such harsh conditions, maintaining the normal opening and closing of valves and ensuring the normal operation of the engine.

◆ High-temperature resistance

Some stainless steel spring plates have good high-temperature resistance and can operate normally in high-temperature environments without losing elasticity or experiencing performance degradation due to excessive temperatures.

In some sealing components of high-temperature equipment, such as the sealing area of industrial furnace doors, using high-temperature resistant stainless steel spring plates can maintain good elasticity in high-temperature environments, effectively achieving sealing functions and preventing heat loss and harmful substance leakage.

Manufacturing process

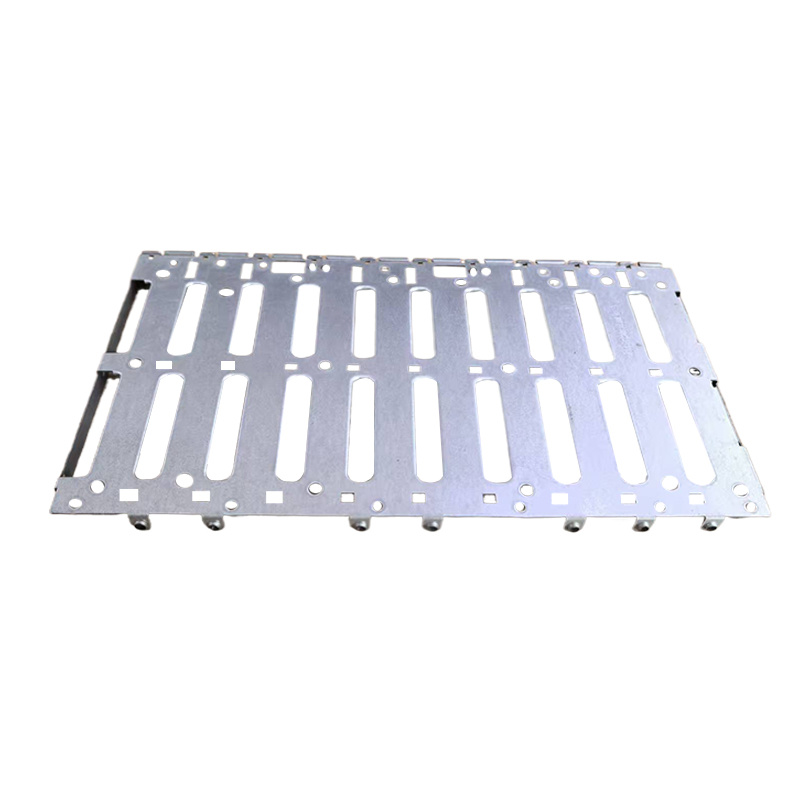

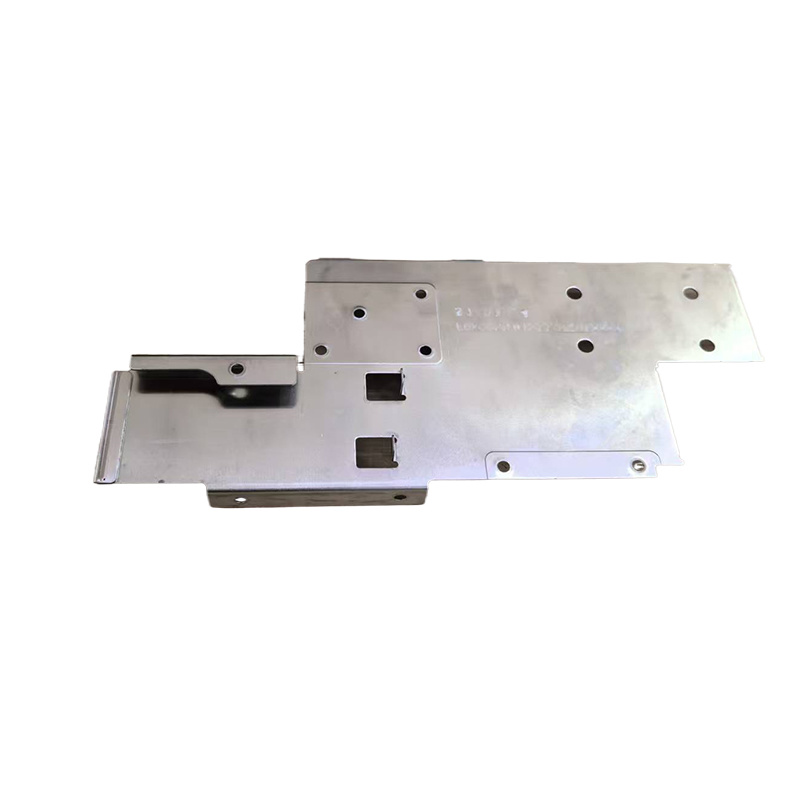

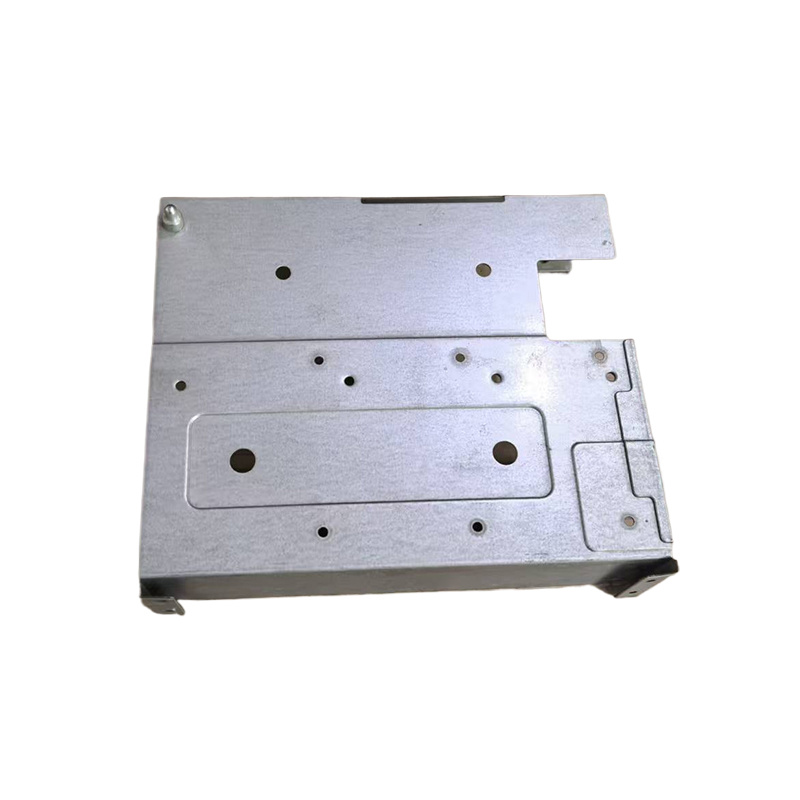

◆ Stamping processing

Stamping is one of the main processing methods for manufacturing stainless steel spring plates. By using molds and stamping equipment, stainless steel sheets are cut, bent, stretched, etc., according to design requirements to form spring plates with specific shapes and sizes.

This process can achieve high efficiency and high precision production, capable of manufacturing various complex-shaped spring plates to meet the needs of different application fields. For example, when producing stainless steel spring plates for mobile phone vibration motors, fine stamping processes can create plates that are only a few millimeters thick but have complex shapes and extremely high precision requirements.

◆ Heat treatment

Heat treatment is an important step in enhancing the performance of stainless steel spring plates. By subjecting stamped spring plates to processes such as quenching and tempering, their microstructure can be adjusted to improve performance indicators such as strength, hardness, and elastic limit.

For instance, after appropriate quenching and tempering treatment, the hardness and elasticity of stainless steel spring plates can be significantly improved, allowing them to better withstand external forces while maintaining stable elastic performance during use.

◆ Surface treatment

Surface treatment processes can improve the surface quality and performance of stainless steel spring plates. Common surface treatment methods include polishing, passivation, electroplating, etc.

Polishing can make the surface of the spring plate smooth and shiny, enhancing its appearance quality; passivation can further enhance the corrosion resistance of the plate; electroplating can coat a layer of other metals on the surface of the plate, such as nickel or chrome plating. This not only improves corrosion resistance but also enhances conductivity and wear resistance. For example, stainless steel spring plates used in some electronic connectors can improve their conductivity and oxidation resistance after gold plating treatment, ensuring good electrical connection performance.

Application fields

◆ Electronic devices

In various electronic devices such as mobile phones, computers, tablets, etc., stainless steel spring plates are widely used in components like keys, switches, vibration motors, antenna springs, etc.

For example, keys on the side of mobile phones typically use stainless steel spring plates to achieve key rebound functionality and provide clear feedback to users; stainless steel spring plates in vibration motors generate vibrations under motor drive to provide vibration alerts for mobile phones.

◆ Automotive manufacturing

Stainless steel spring plates are used in multiple parts of automobiles including engines, transmissions, suspension systems, seat adjustment devices.

For instance, valve spring plates in engines, shifting springs in transmissions, shock-absorbing springs in suspension systems as well as elastic components in seat adjustment devices all play important roles in ensuring normal operation of various automobile parts while providing comfort.

◆ Machinery manufacturing

In various equipment and instruments within the machinery field, stainless steel spring plates are commonly used to manufacture springs, clamps, gaskets, seals and other components.

For example, clamps made from stainless steel spring plates can be used to secure workpieces in machine tool fixtures to ensure stability and precision during processing; in some mechanical structures that require sealing, seals made from stainless steel spring plates can achieve good sealing effects under certain pressures.

◆ Daily necessities

Many daily necessities also feature stainless steel spring plates such as watch straps, eyeglass frames, various stationery clips etc.

The stainless steel spring plate in watch straps provides certain elasticity for easy wearing and adjustment; while the springs in eyeglass frames provide elastic force when opening and closing temple arms ensuring they fit snugly against the head for more comfortable wear.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.