V-cone flow meter

- Commodity name: V-cone flow meter

- Product Description

-

Overview

The V-cone flowmeter measures flow using the throttling effect. Compared to other forms of throttling devices, it changes the throttling layout from traditional central hole throttling to annular throttling. The V-cone uses a streamlined conical body suspended in the center of the pipeline to gradually contract the fluid to the inner wall of the pipeline, giving it self-straightening, self-cleaning, and self-protecting characteristics. It can measure media including liquids, gases, steam, etc., covering almost all flowing media.

Working Principle

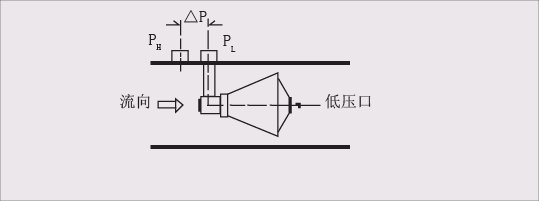

The V-cone flowmeter calculates the flow of fluid conditions based on the principle of flow continuity and Bernoulli's equation. In the same closed pipeline, when pressure decreases, velocity increases. When the medium approaches the cone, its pressure is PH. As the medium passes through the throttling area of the cone, its velocity increases and pressure decreases to PL. As shown in the figure below, both PH and PL are led to the differential pressure transmitter through the pressure tapping points of the V-cone flowmeter. When the flow rate changes, the differential pressure value will increase or decrease accordingly.

Features

◆ Uniform velocity effect on fluid, stable signal, short straight pipe section required for installation;

◆ High accuracy ±0.5%, good repeatability ±0.1%, wide range ratio 10:1;

◆ Wear-resistant, with long-term stability and accuracy, no need for repeated calibration;

◆ Self-cleaning function, dirty fluids will not clog;

◆ The sensor has no electronic components, resistant to high temperatures and vibrations;

◆ Applicable fluids are very wide, diameter: DN15~DN2000;

◆ Low pressure loss, about 1/3 of that of an orifice plate;

◆ Installation methods: flange type, welded type, etc.

Model Representation Method

ZLVZ □□ □□ V-cone flowmeter Nominal Diameter DN (mm) Nominal Pressure PN (MPa) Nominal Pressure Representation Method

Code 00 01 03 04 06 10 16 20 25 28 32 Nominal Pressure (MPa) 0.6 1.6 2.5 4.0 6.4 10 16 20 25 28 32 Nominal Diameter Representation Method

Code 02 03 04 05 06 08 10 12 15 17 20 22 25 Nominal Diameter (mm) 25 32 40 50 65 80 100 125 150 175 200 225 250 Code 27 30 32 35 37 40 45 50 60 70 80 90 99 Nominal Diameter (mm) 275 300 325 350 375 400 450 500 600 700 800 900 1000 For pipe diameters greater than 1000mm, represented as 1/10 of the actual pipe diameter

Technical Parameters

Measured Fluid

◆ Steam: saturated steam, superheated steam

◆ Gas

• Coal gas: coke oven gas, blast furnace gas, city gas

• Natural gas: including natural gas with a moisture content of more than 5%

• Various hydrocarbon gases: alkanes, alkenes and other gases

• Various gas manufacturing: hydrogen, helium, argon, oxygen, nitrogen etc.

• Corrosive gases: wet chloride gases etc.

• Air: including humid air with dust, compressed air etc.

• Flue gas: flue gas emitted from various boilers and heating furnaces

◆ Liquid

• Oils: crude oil, fuel oil, water-containing emulsion oil, diesel oil, hydraulic oil etc.

• Water: raw water, drinking water, production water, sewage etc.

• Various aqueous solutions: acid, alkali, saline solutions etc.

• Organic chemical products: methanol, ethylene glycol, xylene etc.

◆ Special Fluids

• Oil + HC gas + sand

• Gassed water: H2O + N2 + air; H2O + CO2 etc.

◆ Nominal Diameter: DN15-DN2000

◆ Temperature Range: -200℃-500℃

◆ Pressure Level: 1.0MPa-10MPa

◆ Accuracy Level: Grade 0.5—1.5

◆ Material: Cone material is stainless steel (others supplied as per agreement)

◆ β value range: 0.45—0.85

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.