Porous balance flow meter

- Commodity name: Porous balance flow meter

- Product Description

-

Overview

The porous balanced flowmeter consists of a porous orifice plate throttling device, a differential pressure transmitter, and a display instrument.

The porous balanced flowmeter is a flow measuring instrument based on the principle of differential pressure. The structure of this flowmeter combines the orifice plate with a rectifier, opening several holes on a plate based on certain calculations and functional relationships. By measuring the differential pressure on both sides of the orifice plate, flow measurement is achieved. The porous orifice plate throttling device works in conjunction with the differential pressure transmitter and display instrument to measure, display, and accumulate flow.

Due to its special structure, the porous balanced flowmeter is particularly suitable for flow measurement in situations where the straight pipe section is short, the medium is relatively dirty, the flow rate is low, and there are certain requirements for pressure loss. Additionally, its simple structure and ease of installation and maintenance allow for widespread application in industries such as metallurgy, power generation, chemical engineering, textiles, light industry, and heating.

Working Principle

The porous balanced flowmeter is developed based on the orifice plate and operates on the same principle as standard throttling devices, which is based on Bernoulli's equation and the fluid continuity equation. When fluid flows through the porous balanced flowmeter, its velocity increases, resulting in a decrease in static pressure. This creates a static pressure difference before and after the porous orifice plate, allowing for flow measurement through differential pressure measurement (see Figure 1). The square root of the differential pressure is proportional to the flow rate.

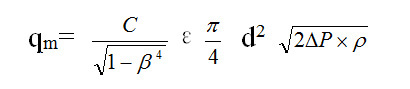

The relationship between mass flow rate and differential pressure is determined by the following formula:

qm——mass flow rate kg/s

C——discharge coefficient dimensionless

β——equivalent diameter ratio of porous orifice plate d/D dimensionless

d——equivalent diameter of porous orifice plate under working conditions m

D——inner diameter of pipeline under working conditions m

ε——expandability coefficient dimensionless

Δp——differential pressure Pa

ρ——density of fluid kg/m³

Product Features3Due to its geometric structure similar to that of a rectifier, the porous balanced flowmeter retains some advantages of orifice plates while also incorporating many benefits of rectifiers. In practical applications, it has the following characteristics:

1. Unique self-rectifying structural design with uniformly symmetrical distribution of throttling holes greatly reduces requirements for straight pipe sections before and after.

2. High measurement accuracy and good repeatability;

3. The porous structure enhances the instrument's resistance to dirt and makes it less prone to clogging;

4. Wide measurement range with low permanent pressure loss, enabling energy conservation and emission reduction;

5. Suitable for measuring bidirectional flow media;

6. Wear-resistant with long-term stability.

Technical Specifications

Applicable Media

Clean and dirty gases, steam, liquids, highly corrosive media, etc. Measurement Accuracy Standard: ≤±0.5%; High precision: ≤±0.2% Repeatability <=±0.1% Range Ratio 10:1~30:1 β Value 0.25~0.9 Scale Differential Pressure <0.1KPa~100KPa Pressure Loss Related to β value and required differential pressure value; it is traditionally about 1/2 to 1/5 of conventional differential pressure flowmeters. Reynolds Number > =200, output signal is linear; <200, output signal requires curve correction. Installation Requirements 'Pipeline type upstream and downstream do not require straight pipe sections; all-round installation. 'Materials 'Carbon steel, chromium-molybdenum steel, stainless steel, duplex steel, Hastelloy, Monel, Inconel,' 'Titanium materials, zirconium materials, aluminum materials, copper materials, plastics, ceramics and other special materials.

'Measurement Pipe Diameter'DN15~DN3000 (round pipes and square pipes), can be larger. 'Applicable Working Conditions 'Flange connection: Design temperature: -196~850℃; Design pressure ≤42.0MPa; 'Direct welding: Related to material selection and wall thickness; theoretically not limited by operating conditions.

'Model Representation Method'Type

'ZLDP'

'□□' 'Porous Balanced Flowmeter' 'Porous Balanced Flowmeter' 'Nominal Diameter DN (mm)'

'Nominal Pressure PN (MPa)' 'Nominal Pressure Representation Method' 'Code'

'Nominal Pressure (MPa)' 00 01 03 04 06 10 16 20 25 28 32 'Nominal Diameter Representation Method' 0.6 1.6 2.5 4.0 6.4 10 16 20 25 28 32 'Nominal Diameter (mm)'

'Nominal Pressure (MPa)' 02 03 04 05 06 08 10 12 15 17 20 22 25 公称直径(mm) 25 32 40 50 65 80 100 125 150 175 200 225 250 'Nominal Pressure (MPa)' 27 30 32 35 37 40 45 50 60 70 80 90 99 公称直径(mm) 275 300 325 350 375 400 450 500 600 700 800 900 1000 For pipe diameters greater than 1000mm, it is expressed as 1/10 of the actual pipe diameter.

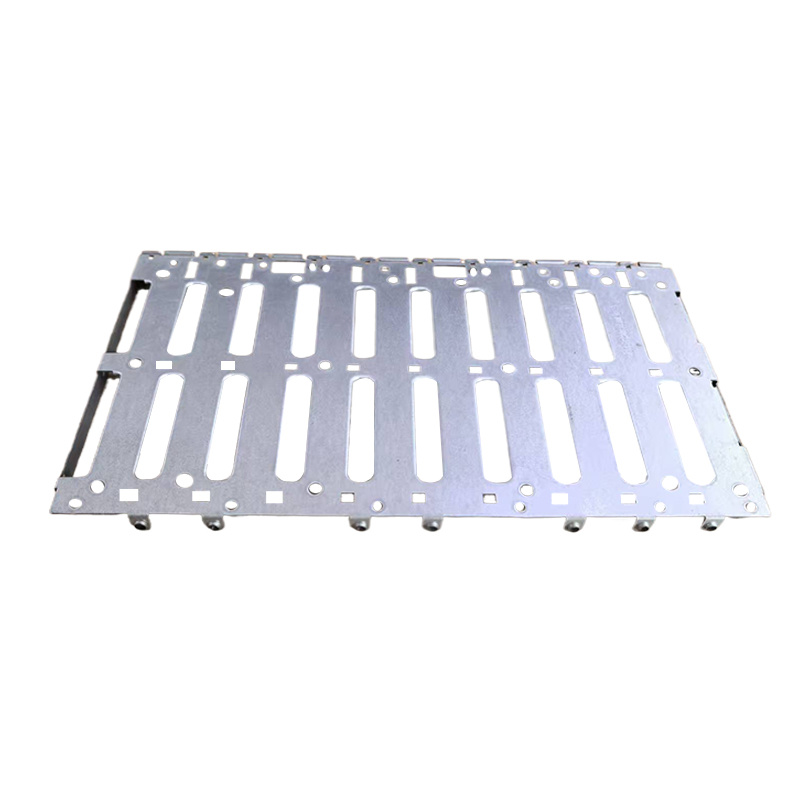

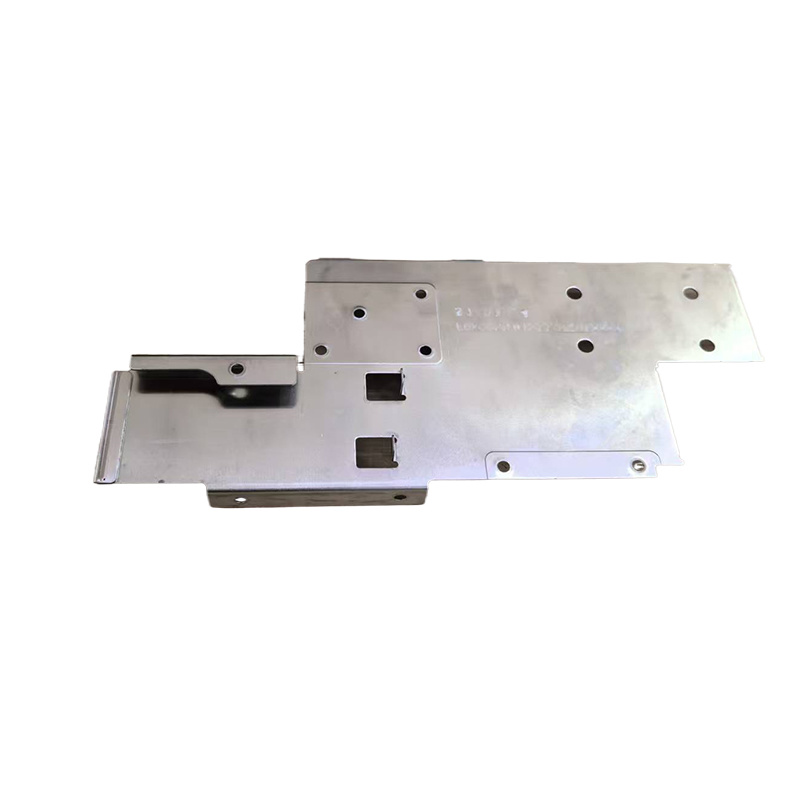

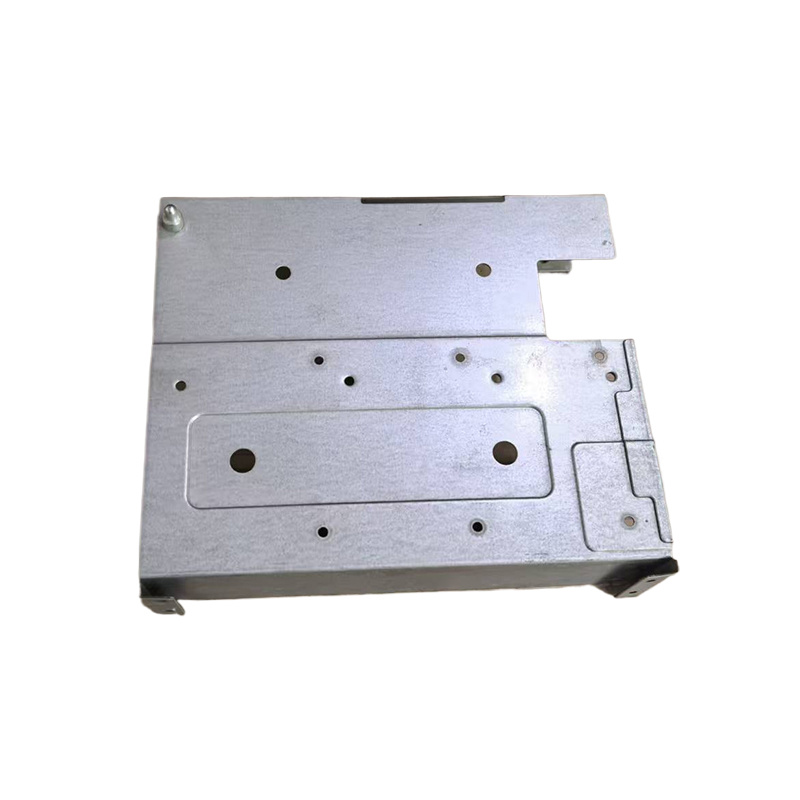

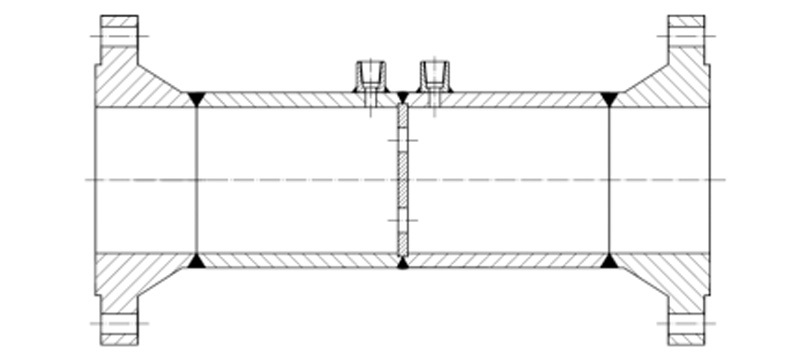

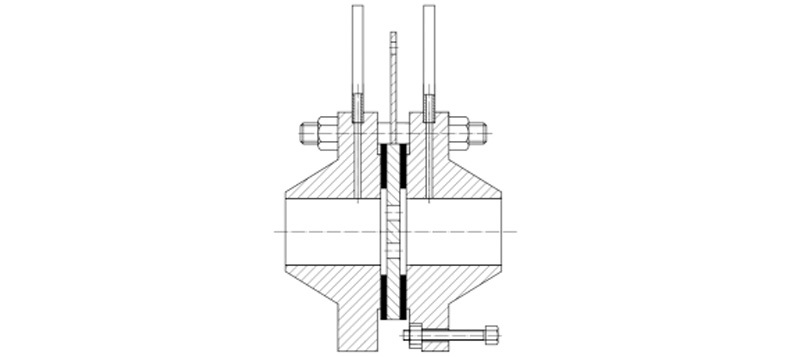

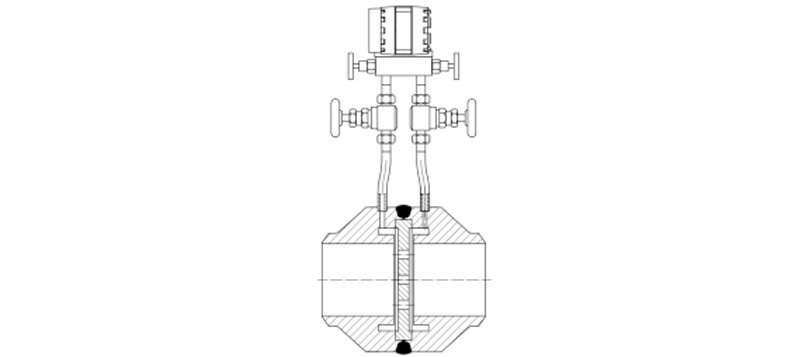

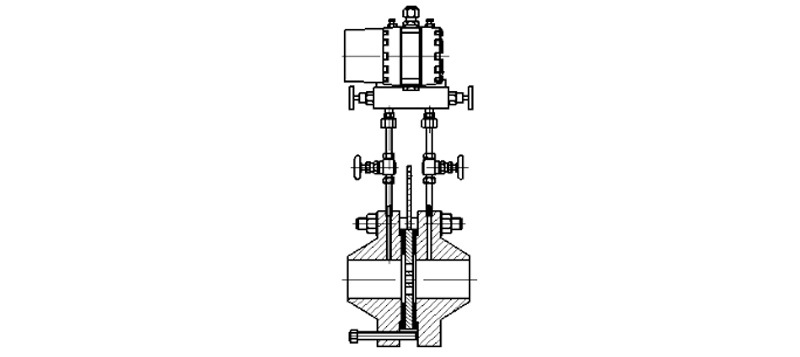

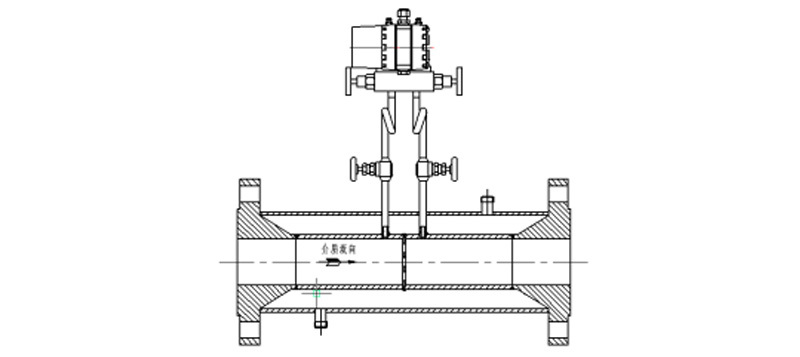

Schematic diagram

Pipe-type multi-hole balanced flow meter

Flange sandwich type multi-hole balanced flow meter

Welded integrated multi-hole balanced flow meter

Flange pressure-taking integrated multi-hole balanced flow meter

Insulated jacket type integrated multi-hole balanced flow meter

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.