Electromagnetic flowmeter

- Commodity name: Electromagnetic flowmeter

- Product Description

-

Overview

The measurement principle of the electromagnetic flowmeter is based on Faraday's electromagnetic induction law, mainly used for measuring the volumetric flow of conductive liquids and slurries in closed pipelines, including highly corrosive liquids such as acids, bases, and salts. Electromagnetic flowmeters are widely used in the production process flow measurement and control in various industrial and agricultural sectors such as petrochemicals, steel metallurgy, water supply and drainage, hydraulic irrigation, water treatment, environmental protection sewage total control, papermaking, pharmaceuticals, and food.

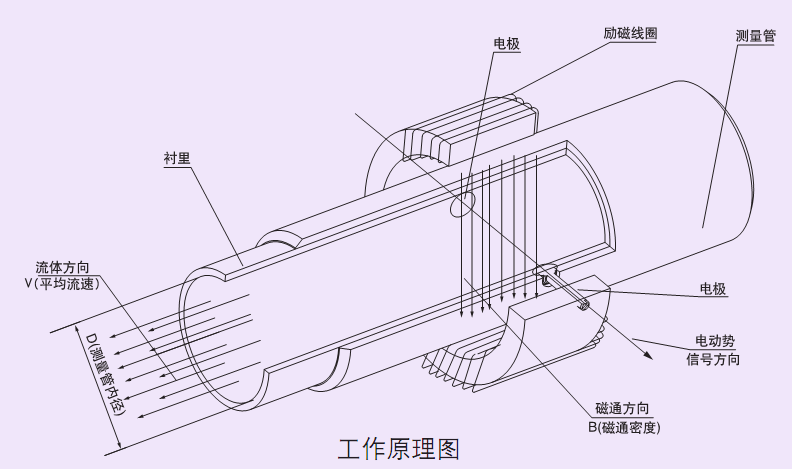

Working Principle

The sensor operates according to Faraday's electromagnetic induction law, as shown in the working principle diagram:

When a conductive liquid moves perpendicular to the magnetic field lines in the measuring tube under an alternating magnetic field, it cuts through the magnetic field lines to generate an induced electric potential. A pair of detection electrodes is installed on the pipe wall perpendicular to both the axis of the measuring tube and the magnetic field lines to detect this induced electric potential. The flow signal is input into a converter, processed by a processor, and then outputs a standard current signal or frequency (pulse) signal. It can also display information such as flow rate, flow volume, percentage of flow on a liquid crystal display, as well as record and adjust flow.

Product Features

◆ There are no resistance or moving parts inside the measuring tube, resulting in no pressure loss; it is a typical energy-saving instrument.

◆ Since the induced signal is formed throughout the space filled with a magnetic field, it is proportional to the average flow velocity across the cross-section of the pipeline. Therefore, it is insensitive to the velocity distribution within the pipeline and requires that the straight pipe sections upstream and downstream of the flowmeter be relatively shorter than those of other flowmeters.

◆ Measurement is not affected by changes in fluid density, viscosity, temperature, pressure, and conductivity.

◆ By reasonably selecting electrode and lining materials, it can meet the requirements for measuring various corrosive and wear-resistant conductive media.

◆ The converter adopts a novel excitation method with low power consumption, stable zero point, high measurement accuracy, suitable for production process flow detection and total measurement. The flow measurement range can reach 1500:1.

◆ The flowmeter has automatic flow direction identification and can measure bidirectional flow. It has current, frequency, pulse, and RS485 digital communication outputs. It also features upper and lower limit alarms for flow and fault alarms.

◆ The flowmeter has a three-level password setting function to prevent data from being arbitrarily changed.

◆ The converter can store setting parameters and cumulative flow values and has a power-off protection function.

◆ The converter uses surface mount technology with self-checking and self-diagnosis functions for high reliability.

◆ It has explosion-proof type, immersion type, sanitary type, split type, and integrated type structures suitable for installation under field environmental conditions.

Types

◆Classified by purpose (see Table 1)

Types Purpose General Type Used in normal environments Explosion-proof Type Used in explosive gas environments Sanitary Type Used under sanitary requirements Immersion Type Complies with GB4208 protection level IP68 Table One

◆Classified by combination type

The classification by combination type of converter and sensor includes: split type and integrated type.

The converter is divided into two structural forms: square shell structure and round shell structure.

Technical Performance Indicators

◆ Nominal diameter (mm): DN10~2000;

◆ Maximum measurement flow rate: 10m/s;

◆ Fluid conductivity ≥ 5μS/cm;

◆ Nominal pressure: DN10~DN50 4.0MPa; DN65~DN150 1.6MPa; DN200~DN1000 1.0MPa; DN1200~DN2000 0.6MPa.

◆ Lining materials: PTFE, PFA, F46, FS etc.

◆ Protection level: IP65, IP68

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.