Innovative Techniques for Stretch Expansion Stamping Parts in Modern Manufacturing

Innovative Techniques for Stretch Expansion Stamping Parts in Modern Manufacturing Manufacturing is constantly evolving, and **stretch expansion stamping** stands at the forefront of this transformation. This advanced technique enhances the production of stamping parts, offering manufacturers increased efficiency, precision, and quality. In this article, we will delve deep into innovative techniqu

Innovative Techniques for Stretch Expansion Stamping Parts in Modern Manufacturing

Manufacturing is constantly evolving, and **stretch expansion stamping** stands at the forefront of this transformation. This advanced technique enhances the production of stamping parts, offering manufacturers increased efficiency, precision, and quality. In this article, we will delve deep into innovative techniques for stretch expansion stamping parts, exploring the latest advancements, applications, and future trends in modern manufacturing.

Table of Contents

- What is Stretch Expansion Stamping?

- History of Stretch Expansion Stamping Techniques

- Innovative Techniques in Stretch Expansion Stamping

- Advanced Materials Used in Stretch Expansion Stamping

- The Role of Computer-Aided Design (CAD)

- Automation and AI in Manufacturing

- Applications of Stretch Expansion Stamping Parts

- Challenges and Solutions in Stretch Expansion Stamping

- The Future of Stretch Expansion Stamping

- Conclusion

- FAQs

What is Stretch Expansion Stamping?

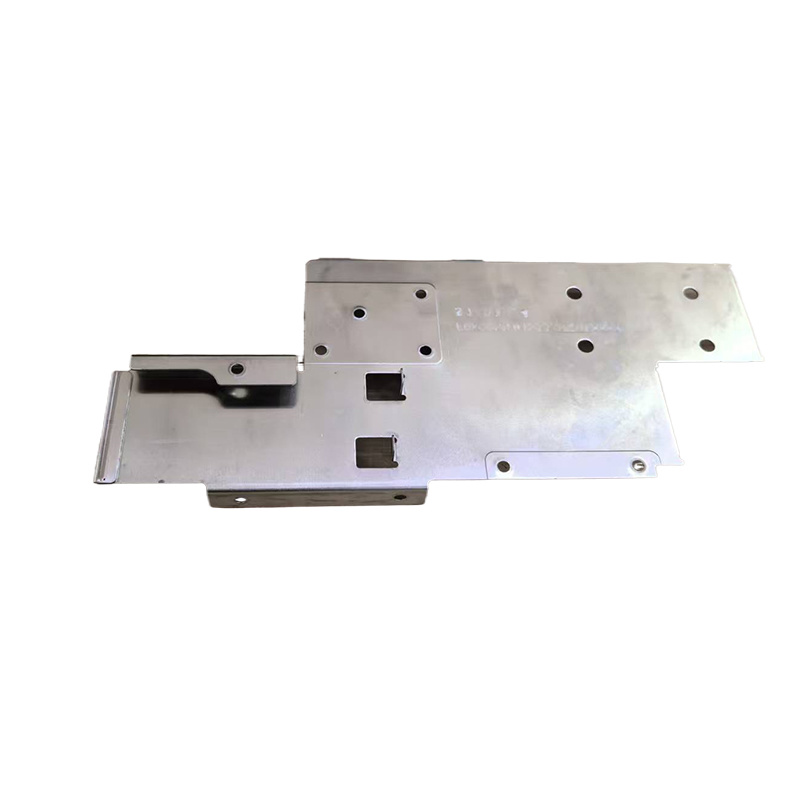

**Stretch expansion stamping** is a unique manufacturing process that involves the deformation of sheet metal into a desired shape. This method combines traditional stamping techniques with stretching, allowing for the creation of complex geometries with a smooth finish. Unlike conventional stamping, which often results in material thinning, stretch expansion stamping maintains material integrity while achieving significant dimensional accuracy.

The process typically involves clamping the metal sheet and applying a stretching force while simultaneously stamping it into a mold. This combination of forces leads to a more controlled shaping of the material, resulting in intricate designs that are highly sought after in various industries.

History of Stretch Expansion Stamping Techniques

The origins of stretch expansion stamping can be traced back to the early 20th century, when manufacturers sought more efficient ways to produce complex metal parts. Initially, stamping involved simple shapes and relied heavily on manual labor. However, as technology progressed, so did the methods of production.

In the 1960s and 1970s, the introduction of advanced hydraulic presses and CNC machines revolutionized the stamping industry. This period marked the beginning of automated stamping techniques, allowing for greater precision. The development of stretch expansion stamping in the late '90s offered a new avenue for producing lightweight, strong parts, especially in the automotive and aerospace sectors.

Innovative Techniques in Stretch Expansion Stamping

Recent advancements in **stretch expansion stamping** have led to the emergence of several innovative techniques that enhance productivity and quality.

Advanced Materials Used in Stretch Expansion Stamping

The choice of materials in stretch expansion stamping plays a crucial role in the quality of the final product. Manufacturers are increasingly turning to high-strength steels, aluminum alloys, and composite materials that offer enhanced properties. These materials not only reduce weight but also improve durability and resistance to corrosion.

Advanced materials enable manufacturers to achieve complex geometries without compromising the structural integrity of the parts. For instance, using aluminum alloys can lead to significant weight reductions in automotive components, thereby improving fuel efficiency.

The Role of Computer-Aided Design (CAD)

**Computer-Aided Design (CAD)** has transformed the manufacturing landscape, allowing engineers to create intricate designs and simulate the stretch expansion stamping process before actual production. CAD software facilitates the visualization of the part's geometry, making it easier to identify potential issues and optimize the design.

Moreover, CAD programs can integrate with simulation tools to predict material behavior under various conditions, leading to improved accuracy and reduced waste. This combination of design and simulation ensures that manufacturers can achieve high precision in their stamping parts.

Automation and AI in Manufacturing

The integration of **automation and artificial intelligence (AI)** into stretch expansion stamping processes has created new opportunities for efficiency and productivity. Automated systems can handle repetitive tasks, allowing human operators to focus on more complex aspects of production.

AI-driven analytics can optimize the stamping process by analyzing data in real-time, predicting failures, and facilitating preventative maintenance. This technology enables manufacturers to reduce downtime and improve overall production rates, resulting in cost savings and increased profitability.

Applications of Stretch Expansion Stamping Parts

Stretch expansion stamping finds applications across various industries, driven by the need for lightweight, durable, and complex components.

In the **automotive industry**, manufacturers utilize stretch expansion stamping to create body panels, brackets, and structural components that enhance vehicle performance and safety. The lightweight nature of stamped parts contributes to improved fuel efficiency and reduced emissions.

In the **aerospace sector**, stretch expansion stamping is crucial for producing parts that require high strength-to-weight ratios. Components such as wing structures and fuselage sections benefit from this manufacturing technique, ensuring structural integrity while minimizing weight.

Moreover, industries such as **electronics** and **appliances** are increasingly adopting stretch expansion stamping to produce intricate housings and components that enhance product aesthetics and functionality.

Challenges and Solutions in Stretch Expansion Stamping

Despite the advantages of stretch expansion stamping, manufacturers face several challenges that can hinder production efficiency and quality.

One of the primary challenges is **material wrinkling**, which can occur during the stretching process. To mitigate this issue, manufacturers employ techniques such as using tailored blanking methods, which involve pre-cutting the metal sheet to match the part's geometry. This approach minimizes excess material and reduces the likelihood of wrinkles.

Additionally, achieving consistent quality can be challenging due to variations in material properties. Implementing strict quality control measures and using advanced monitoring systems can help maintain consistency throughout the production process.

Furthermore, the initial investment in advanced machinery and technology can be a barrier for some manufacturers. However, the long-term benefits of increased efficiency and reduced waste typically outweigh the upfront costs.

The Future of Stretch Expansion Stamping

Looking ahead, stretch expansion stamping is set to play a pivotal role in the future of manufacturing. As industries continue to demand lightweight and efficient components, the technique will likely evolve to incorporate even more advanced materials and technologies.

Emerging trends such as **3D printing** and **hybrid manufacturing** may further complement stretch expansion stamping, enabling manufacturers to explore new design possibilities and production methods. The integration of sustainable practices will also shape the future landscape, with an emphasis on recycling and reducing the environmental impact of manufacturing processes.

To remain competitive, manufacturers must continuously innovate and adapt, embracing new technologies and methodologies in stretch expansion stamping.

Conclusion

In conclusion, innovative techniques for stretch expansion stamping parts have revolutionized modern manufacturing, offering increased precision, efficiency, and quality. As industries continue to evolve, the demand for lightweight and durable components will drive further advancements in this field. By leveraging advanced materials, automation, and cutting-edge design software, manufacturers can overcome challenges and fulfill the needs of a dynamic market. The future of stretch expansion stamping is bright, with limitless possibilities for innovation and growth.

FAQs

1. What is the primary advantage of stretch expansion stamping?

The primary advantage lies in its ability to produce complex geometries with minimal material thinning, maintaining structural integrity while enhancing dimensional accuracy.

2. What types of materials are best suited for stretch expansion stamping?

High-strength steels, aluminum alloys, and composite materials are commonly used due to their lightweight and durable properties.

3. How does CAD improve the stretch expansion stamping process?

CAD allows for precise design and simulation of parts, helping to identify potential issues early in the production process and optimizing designs for better outcomes.

4. What role does automation play in stretch expansion stamping?

Automation streamlines repetitive tasks, enhances production speed, reduces human error, and allows operators to focus on more complex aspects of manufacturing.

5. What are some challenges faced in stretch expansion stamping?

Challenges include material wrinkling, achieving consistent quality, and the initial investment in advanced equipment. Addressing these issues requires careful planning and implementation of quality control measures.

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.