How Precision Metal Stamping Revolutionizes the Production Process

How Precision Metal Stamping Revolutionizes the Production Process In today's fast-paced manufacturing landscape, the need for efficiency, precision, and quality is more critical than ever. Among the various methods employed in the production of metal parts, **precision metal stamping** has emerged as a game-changer. This sophisticated technique not only enhances productivity but also ensures that

How Precision Metal Stamping Revolutionizes the Production Process

In today's fast-paced manufacturing landscape, the need for efficiency, precision, and quality is more critical than ever. Among the various methods employed in the production of metal parts, **precision metal stamping** has emerged as a game-changer. This sophisticated technique not only enhances productivity but also ensures that products meet stringent quality standards. This article delves into how precision metal stamping is revolutionizing the production process, offering insights that can help businesses optimize their operations and remain competitive in the market.

Table of Contents

- Understanding Metal Stamping: A Comprehensive Overview

- Precision Metal Stamping vs. Conventional Stamping Techniques

- Benefits of Precision Metal Stamping in Manufacturing

- Diverse Applications of Precision Metal Stamping

- The Metal Stamping Process: A Step-by-Step Guide

- Future Trends in Precision Metal Stamping Technology

- Choosing the Right Partner for Precision Metal Stamping

- Frequently Asked Questions about Precision Metal Stamping

- Conclusion: Embracing the Future of Manufacturing with Precision Metal Stamping

Understanding Metal Stamping: A Comprehensive Overview

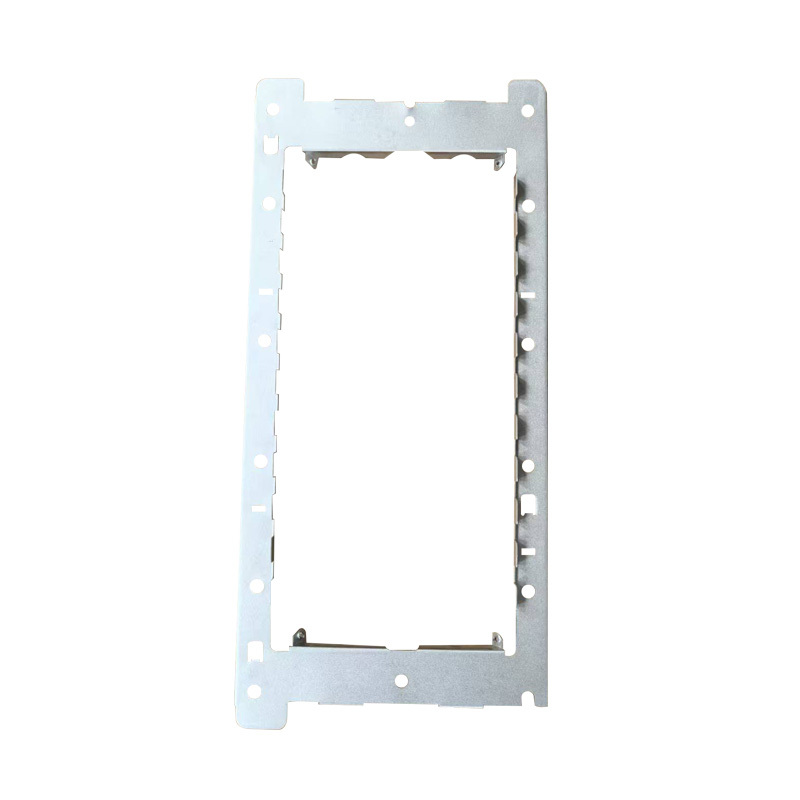

Metal stamping is a manufacturing process that involves converting flat metal sheets into specific shapes through a series of operations, which may include bending, flanging, and punching. This process is pivotal in producing various industrial components, from automotive parts to consumer electronics. **Precision metal stamping**, in particular, utilizes advanced technologies to achieve high levels of accuracy and repeatability, enabling manufacturers to create complex designs and intricate details with minimal waste.

The Evolution of Metal Stamping

Historically, metal stamping was a labor-intensive process that relied heavily on manual labor and rudimentary tools. However, technological advancements have significantly transformed this industry. Today, **CNC (Computer Numerical Control)** machines, robotics, and laser cutting technologies are standard, allowing for quick adjustments and complex designs that were previously unattainable.

Precision Metal Stamping vs. Conventional Stamping Techniques

While conventional stamping methods still play a role in certain manufacturing sectors, precision metal stamping has distinct advantages. The key difference lies in the accuracy and repeatability of the parts produced. Precision stamping techniques, often guided by computer-aided design (CAD) software, minimize tolerances and ensure that every component meets exact specifications, which is crucial for industries such as aerospace and medical equipment manufacturing.

Cost Efficiency and Waste Reduction

One of the most significant advantages of precision metal stamping is its cost efficiency. By producing parts with minimal waste, manufacturers can reduce material costs and improve their overall profit margins. Moreover, the speed of production allows for shorter lead times, ensuring that companies can meet market demands swiftly without compromising quality.

Benefits of Precision Metal Stamping in Manufacturing

Enhanced Quality Control

Precision metal stamping provides manufacturers with enhanced quality control mechanisms. The use of automated systems and real-time monitoring allows for immediate detection of defects, ensuring that only parts meeting the highest standards leave the production line. This level of quality assurance is vital for maintaining customer satisfaction and building brand reputation.

Versatility in Design

Another remarkable benefit of precision metal stamping is the versatility it offers in design. Manufacturers can create a wide array of components, from simple brackets to complex assemblies, all with high precision. The ability to produce various shapes and sizes makes precision stamping an ideal choice for industries with diverse product lines.

Shorter Production Cycles

With advancements in technology, precision metal stamping allows for shorter production cycles. The process integrates seamlessly with automated assembly lines, which speeds up the entire manufacturing process. This not only enhances productivity but also reduces time-to-market for new products.

Diverse Applications of Precision Metal Stamping

Precision metal stamping is utilized across various industries, demonstrating its versatility and effectiveness. Some notable applications include:

Automotive Industry

The automotive industry benefits significantly from precision metal stamping, as it requires high-quality components that meet strict safety and performance standards. From chassis parts to engine components, precision stamping ensures that each piece is manufactured with precision and durability.

Electronics Manufacturing

In the electronics sector, precision metal stamping is crucial for producing intricate components such as connectors, brackets, and housings. The high precision required in these parts is essential for ensuring the functionality and reliability of electronic devices.

Medical Equipment Production

Medical devices demand the highest standards of quality and precision. Precision metal stamping plays a vital role in producing components for surgical instruments, diagnostic devices, and other essential medical equipment, ensuring they are safe and effective for use.

The Metal Stamping Process: A Step-by-Step Guide

1. Design and Prototyping

Before any stamping occurs, the design phase is critical. Engineers use CAD software to create detailed models of the parts, allowing for prototyping and testing before full-scale production begins. This step ensures that any potential design flaws are addressed early in the process.

2. Material Selection

The choice of material is vital in the stamping process. **Steel, aluminum, and copper** are commonly used metals, each offering unique properties that can affect the final product's performance. Engineers must select materials based on the end-use requirements and desired characteristics.

3. Tooling Setup

Once the design and materials are finalized, the tooling setup begins. This involves creating the dies that will shape the metal during stamping. High-quality tooling is essential for achieving the desired precision and ensuring the longevity of the stamping dies.

4. Stamping Operations

The actual stamping process involves placing the metal sheet into the stamping machine, which applies force to shape the metal according to the die design. This step may involve multiple operations, including cutting, bending, and forming, often performed in a single run to maximize efficiency.

5. Quality Inspection

After the stamping process, each component undergoes rigorous quality inspections. Automated systems may be used to check for dimensional accuracy, surface finish, and other critical factors to ensure compliance with industry standards.

6. Finishing and Assembly

Finally, components may require additional finishing processes, such as coating or plating, to enhance their durability and appearance. Many manufacturers also offer assembly services, combining multiple stamped parts into a complete product ready for shipment.

Future Trends in Precision Metal Stamping Technology

The future of precision metal stamping holds exciting possibilities, driven by technological advancements and industry demands. Key trends include:

1. Increased Automation

As industries continue to seek efficiency, automation in precision metal stamping will likely increase. Automated systems will streamline processes, reduce human error, and enhance production speeds.

2. Integration of Additive Manufacturing

The integration of **additive manufacturing** in conjunction with metal stamping may open new avenues for creating complex geometries that are difficult to achieve with traditional methods. This hybrid approach could revolutionize how components are designed and manufactured.

3. Sustainable Practices

With growing environmental concerns, manufacturers are adopting sustainable practices in metal stamping. This includes utilizing recycled materials, reducing energy consumption during production, and implementing waste reduction strategies.

Choosing the Right Partner for Precision Metal Stamping

Selecting the right partner for precision metal stamping is crucial for ensuring quality and reliability. When evaluating potential suppliers, consider the following factors:

1. Experience and Expertise

Look for a partner with a proven track record in precision metal stamping. Their experience can provide valuable insights and contributions to your project, ensuring that you receive the best possible service.

2. Technological Capabilities

Assess the technological capabilities of potential partners. Advanced machinery and up-to-date techniques are essential for achieving the high precision required in today’s manufacturing environment.

3. Quality Assurance Processes

Inquire about the quality assurance processes in place. A reputable partner should have stringent quality control measures to guarantee that every part meets your specifications and standards.

4. Customer Support and Communication

Effective communication and reliable customer support are vital for a successful partnership. Ensure that your chosen partner is responsive and willing to collaborate throughout the production process.

Frequently Asked Questions about Precision Metal Stamping

What is precision metal stamping?

Precision metal stamping is a manufacturing process that involves shaping flat metal sheets into specific forms using advanced technology and techniques, ensuring high accuracy and quality.

What industries use precision metal stamping?

Precision metal stamping is utilized in various industries, including automotive, electronics, medical devices, and aerospace, due to its versatility and ability to produce high-quality components.

How does precision metal stamping enhance efficiency?

This technique reduces material waste, shortens production cycles, and allows for quick adjustments, thus enhancing overall manufacturing efficiency.

What materials are commonly used in precision metal stamping?

Common materials include steel, aluminum, and copper, chosen based on the specific needs and characteristics required for the end product.

Are there sustainable practices in precision metal stamping?

Yes, many manufacturers are adopting sustainable practices such as using recycled materials and implementing waste reduction strategies to minimize their environmental impact.

Conclusion: Embracing the Future of Manufacturing with Precision Metal Stamping

**Precision metal stamping** represents a significant advancement in manufacturing processes, offering unparalleled accuracy, efficiency, and versatility. As industries continue to evolve, embracing this technology can lead to improved product quality and reduced production costs. By understanding the benefits, applications, and future trends of precision metal stamping, businesses can position themselves for success in an increasingly competitive market. Investing in precision metal stamping not only enhances operational efficiency but also helps companies meet the growing demands of their customers, paving the way for a brighter manufacturing future.

Previous:

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.