Why Gas Turbine Flow Meters Are Essential for Accurate Measurements in Industrial Applications

Why Gas Turbine Flow Meters Are Essential for Accurate Measurements in Industrial Applications Table of Contents 1. Introduction to Gas Turbine Flow Meters 2. How Gas Turbine Flow Meters Work 3. Advantages of Using Gas Turbine Flow Meters 4. Industrial Applications of Gas Turbine Flow Meters 5. Accuracy and Reliability: Key Features Explained 6. Maintenance Best Practices

Why Gas Turbine Flow Meters Are Essential for Accurate Measurements in Industrial Applications

Table of Contents

- 1. Introduction to Gas Turbine Flow Meters

- 2. How Gas Turbine Flow Meters Work

- 3. Advantages of Using Gas Turbine Flow Meters

- 4. Industrial Applications of Gas Turbine Flow Meters

- 5. Accuracy and Reliability: Key Features Explained

- 6. Maintenance Best Practices for Gas Turbine Flow Meters

- 7. Choosing the Right Gas Turbine Flow Meter

- 8. FAQs About Gas Turbine Flow Meters

- 9. Conclusion

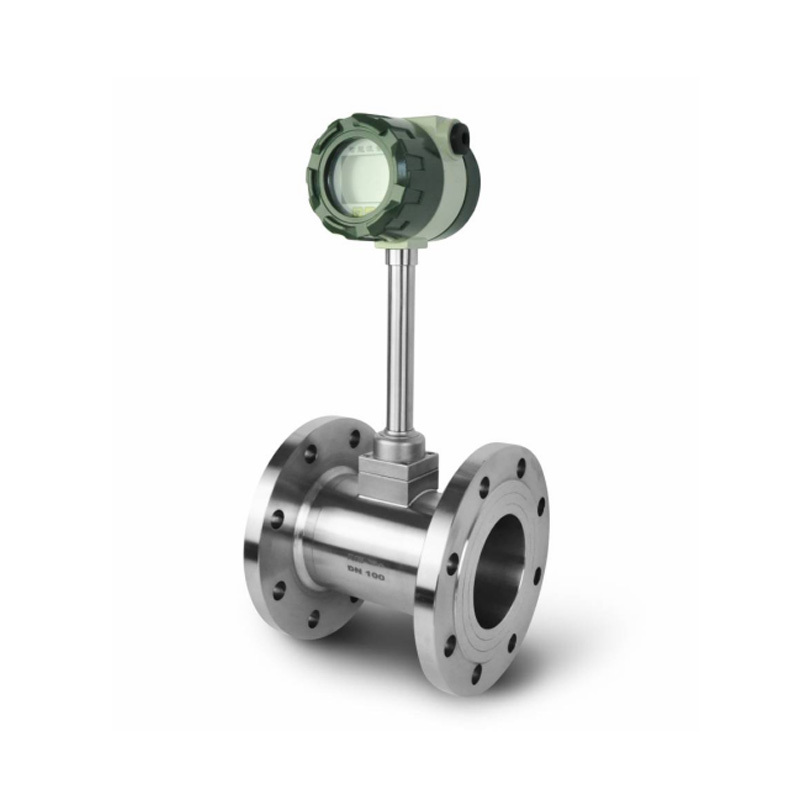

1. Introduction to Gas Turbine Flow Meters

Gas turbine flow meters have emerged as a vital component in the realm of industrial measurement. They provide precise flow measurement of gases and liquids, proving indispensable across various sectors, including oil and gas, chemical processing, and water treatment. With the demand for **accurate data** rising, understanding the mechanisms and advantages of gas turbine flow meters becomes essential for industries aiming for efficiency and compliance.

2. How Gas Turbine Flow Meters Work

At the heart of gas turbine flow meters lies a straightforward yet effective operation principle. These devices utilize a rotor with blades that spin when fluid flows through the meter. As the fluid moves, it imparts energy to the rotor, causing it to spin at a speed proportional to the flow rate. This rotational speed is then measured using advanced sensors, which convert it into an electrical signal that corresponds to the flow measurement.

This method allows for **real-time monitoring** and precise calculations, making gas turbine flow meters highly reliable. In contrast to other types of flow meters, their design minimizes pressure drop, ensuring efficient operation without compromising the flow of gases or liquids.

3. Advantages of Using Gas Turbine Flow Meters

Gas turbine flow meters offer numerous advantages that make them a preferred choice for industrial applications:

3.1 High Accuracy

Gas turbine flow meters provide **exceptional accuracy** in flow measurement, often within ±0.5% of the reading. This level of precision is critical for industries where even slight errors can result in significant financial losses or safety hazards.

3.2 Wide Measurement Range

These flow meters can handle a wide range of flow rates, making them suitable for various applications. They effectively measure both low and high flow rates, accommodating changing operational conditions.

3.3 Low Maintenance Costs

Due to their robust design, gas turbine flow meters require minimal maintenance, translating to lower operational costs. Regular inspections and occasional calibration are usually sufficient to keep them functioning optimally.

3.4 Versatility

Gas turbine flow meters can be used for different types of applications, including measuring liquids, gases, and steam. Their versatility allows businesses to utilize them across multiple processes within their operations.

4. Industrial Applications of Gas Turbine Flow Meters

Gas turbine flow meters serve multiple industrial sectors, reflecting their adaptability and reliability:

4.1 Oil and Gas Industry

In the oil and gas sector, accuracy is paramount. Gas turbine flow meters are often employed to measure natural gas flow in pipelines, ensuring that transportation and processing remain efficient and cost-effective.

4.2 Chemical Processing

Chemical plants rely on precise flow measurements for various processes. Gas turbine flow meters help maintain optimal conditions for chemical reactions, ensuring safety and efficiency in operations.

4.3 Water and Wastewater Treatment

In water treatment facilities, accurate flow measurement is essential for regulating the treatment process. Gas turbine flow meters assist in monitoring water flow rates, enabling effective management of resources.

4.4 HVAC Applications

In heating, ventilation, and air conditioning (HVAC) systems, gas turbine flow meters can help optimize energy consumption by providing accurate data on air and gas flow rates, thus enhancing overall system efficiency.

5. Accuracy and Reliability: Key Features Explained

The accuracy and reliability of gas turbine flow meters stem from several design features:

5.1 Precision Engineering

Manufactured from high-quality materials, gas turbine flow meters are designed to withstand varying operational conditions, ensuring longevity and performance.

5.2 Advanced Sensor Technology

The integration of advanced sensor technology enhances the ability to detect minute changes in flow rates, contributing to their high accuracy.

5.3 Calibration and Validation Procedures

Regular calibration and validation procedures are maintained to ensure measurement accuracy, further affirming the reliability of gas turbine flow meters in critical applications.

6. Maintenance Best Practices for Gas Turbine Flow Meters

While gas turbine flow meters are relatively low maintenance, implementing best practices helps optimize their performance:

6.1 Regular Inspections

Routine inspections should be performed to identify any wear and tear, ensuring the meter remains in top condition.

6.2 Calibration

Periodic calibration is essential to maintain accuracy. This process should follow the manufacturer’s recommendations and industry standards.

6.3 Cleaning

Keeping the flow path clear of debris is crucial. Regular cleaning can prevent blockages that may affect the meter's performance.

7. Choosing the Right Gas Turbine Flow Meter

Selecting the appropriate gas turbine flow meter for specific applications requires careful consideration of several factors:

7.1 Flow Rate Requirements

Understanding the expected flow rates is crucial in selecting a meter that can handle the specific demands of the application.

7.2 Fluid Characteristics

The physical and chemical properties of the fluid being measured, such as viscosity and temperature, must be evaluated to ensure compatibility with the flow meter.

7.3 Environmental Conditions

Consideration should be given to the environment in which the flow meter will operate, including temperature extremes, pressure levels, and exposure to corrosive substances.

8. FAQs About Gas Turbine Flow Meters

8.1 What are gas turbine flow meters used for?

Gas turbine flow meters are primarily used to measure the flow rates of gases and liquids in various industrial applications, ensuring accurate monitoring and control.

8.2 How often should gas turbine flow meters be calibrated?

Calibration frequency depends on the specific application and environmental conditions, but it’s typically recommended to calibrate at least once a year.

8.3 Can gas turbine flow meters measure both gases and liquids?

Yes, gas turbine flow meters are versatile and can accurately measure both gases and liquids, making them suitable for a range of applications.

8.4 What is the typical accuracy of gas turbine flow meters?

Gas turbine flow meters typically offer accuracy levels of ±0.5% of the reading, making them highly reliable for precision measurements.

8.5 Are gas turbine flow meters suitable for high-temperature applications?

Yes, many gas turbine flow meters are designed to withstand high temperatures, but it’s essential to choose a model specifically rated for such conditions.

9. Conclusion

Gas turbine flow meters play a fundamental role in ensuring accurate flow measurements across diverse industrial applications. Their combination of precision, reliability, and low maintenance makes them a valuable asset for businesses striving for efficiency and compliance. By understanding their operation, advantages, and applications, industries can leverage these instruments to enhance their processes, reduce costs, and ensure safety in operations. Investing in high-quality gas turbine flow meters is not just a choice; it's a necessary step toward achieving operational excellence in today's competitive landscape.

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.