The Essential Role of High Precision Stamping Parts in Streamlining Production Lines

The Essential Role of High Precision Stamping Parts in Streamlining Production Lines In today’s fast-paced manufacturing landscape, **high precision stamping parts** have emerged as a cornerstone of efficient production lines. These components, integral to a wide array of industries, not only ensure part accuracy but also optimize operational workflows. In this article, we will delve into the sign

The Essential Role of High Precision Stamping Parts in Streamlining Production Lines

In today’s fast-paced manufacturing landscape, **high precision stamping parts** have emerged as a cornerstone of efficient production lines. These components, integral to a wide array of industries, not only ensure part accuracy but also optimize operational workflows. In this article, we will delve into the significance of high precision stamping parts, their applications, and how they contribute to enhanced production efficiency.

Table of Contents

- What Are High Precision Stamping Parts?

- The Importance of High Precision in Manufacturing

- Applications of High Precision Stamping Parts

- Advantages of High Precision Stamping for Production Lines

- Technological Advancements in Stamping Technology

- Challenges in High Precision Stamping and Solutions

- The Future of High Precision Stamping Parts in Manufacturing

- Conclusion

- FAQs

What Are High Precision Stamping Parts?

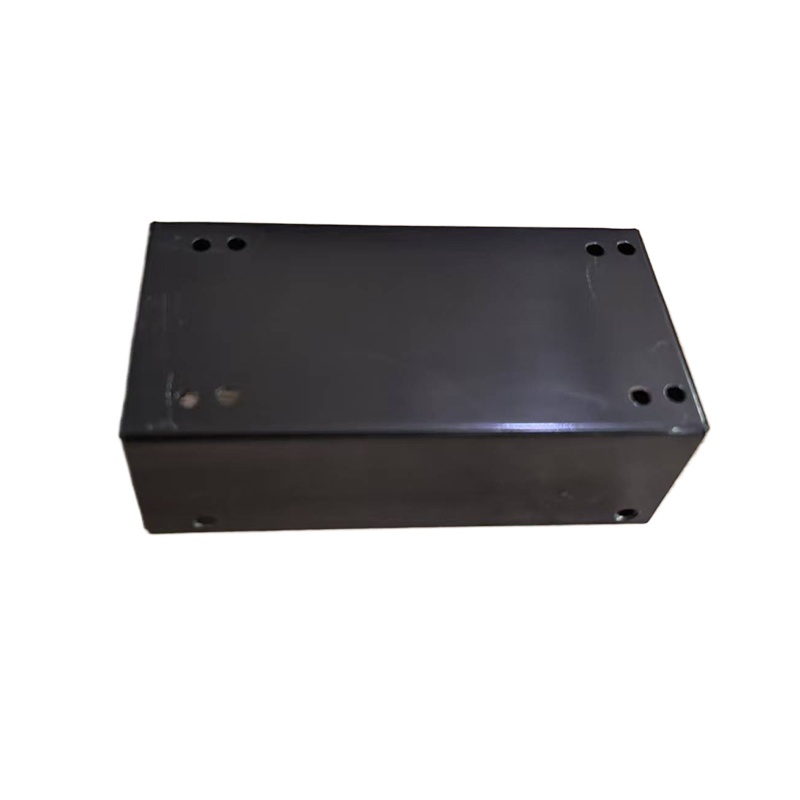

High precision stamping parts are manufactured through a process that involves shaping metal sheets into desired forms using various stamping techniques. These parts are characterized by their exact dimensions, tight tolerances, and superior surface finishes. The **stamping process** can include methods such as blanking, punching, bending, and deep drawing, all designed to produce intricate components that meet stringent industry standards.

The materials used for high precision stamping often include steel, aluminum, brass, and other alloys, chosen based on the specific application requirements. Manufacturers rely on these parts in various sectors, including automotive, electronics, aerospace, and medical equipment, where precision and reliability are paramount.

The Importance of High Precision in Manufacturing

In the realm of manufacturing, accuracy is vital. High precision stamping parts play a crucial role in ensuring that assembled products function correctly and meet quality standards. Here are several reasons why precision is so important:

1. Enhancing Product Quality

Precision components reduce the risk of defects in the final product, leading to higher quality outcomes. This is especially critical in industries such as aerospace and medical, where safety and reliability cannot be compromised.

2. Reducing Waste

By producing parts that fit together seamlessly, manufacturers can minimize waste and scrap. This is economically beneficial as it reduces material costs and enhances overall production efficiency.

3. Improving Assembly Processes

High precision parts ensure that assemblies fit properly, leading to quicker assembly times and less need for rework. This contributes to a more efficient production line, allowing manufacturers to meet deadlines and improve output.

Applications of High Precision Stamping Parts

High precision stamping parts are utilized in a wide range of applications across various industries. Let’s explore some of the most prominent areas where these components are essential.

1. Automotive Industry

In the automotive sector, high precision stamping parts are used to produce components like brackets, connectors, and chassis parts. The need for lightweight yet robust materials drives the demand for advanced stamping techniques that produce high-quality components.

2. Electronics Manufacturing

Electronic devices require precise components such as circuit boards, connectors, and housings. High precision stamping ensures these parts meet the tight tolerances necessary for functionality and performance.

3. Aerospace Components

The aerospace industry demands the highest levels of precision for safety-critical components. High precision stamping is used to manufacture parts such as engine components, structural parts, and fasteners, which must withstand extreme conditions.

4. Medical Devices

In medical manufacturing, precision is crucial. Stamping parts for devices like surgical instruments and diagnostic equipment must meet rigorous standards for accuracy and reliability.

5. Consumer Goods

Many consumer products incorporate high precision stamped parts, from appliances to furniture. These components contribute to aesthetics and functionality, enhancing the overall user experience.

Advantages of High Precision Stamping for Production Lines

The integration of high precision stamping parts into production lines offers numerous advantages that contribute to overall efficiency and effectiveness. Here are some key benefits:

1. Cost Efficiency

High precision stamping reduces the material waste associated with traditional manufacturing techniques. By optimizing the process, manufacturers can lower production costs while maintaining high quality.

2. Scalability

Modern stamping technology supports large-scale production without compromising quality. As demand increases, manufacturers can easily scale operations to meet production requirements.

3. Speed and Efficiency

High precision stamping processes are designed for rapid production cycles. This speed allows manufacturers to respond quickly to market demands and reduce lead times.

4. Design Flexibility

The versatility of stamping techniques allows for the creation of complex geometries and designs. This flexibility ensures that manufacturers can innovate and adapt to changing consumer preferences.

5. Increased Reliability

High precision parts reduce the likelihood of failure in final products. This reliability enhances brand reputation and customer satisfaction, crucial factors for long-term success.

Technological Advancements in Stamping Technology

The stamping industry has seen significant advancements in technology that enhance the precision and efficiency of production lines. Some of the most notable developments include:

1. Automation and Robotics

Automated stamping machines and robotics have revolutionized the manufacturing process. These technologies improve speed, consistency, and safety, allowing for higher production rates with reduced labor costs.

2. Advanced Materials

The introduction of new materials, such as high-strength alloys and composites, has expanded the capabilities of high precision stamping. These materials offer improved performance while maintaining the benefits of weight reduction.

3. Computer-Aided Design (CAD) and Simulation

Modern CAD software allows engineers to design and simulate stamping processes before production begins. This leads to optimized designs that reduce errors and enhance manufacturing efficiency.

4. Smart Manufacturing and IoT

The incorporation of Internet of Things (IoT) technology in stamping presses enables real-time monitoring and data analysis. This connectivity allows manufacturers to identify bottlenecks and optimize production processes dynamically.

5. Enhanced Tooling Technologies

Advancements in tooling technology, such as progressive dies and multi-slide stamping, enable the production of complex parts with high precision. This enhances the overall productivity of manufacturing operations.

Challenges in High Precision Stamping and Solutions

Despite the advantages of high precision stamping, manufacturers face several challenges. Identifying these challenges and implementing effective solutions is crucial for maintaining efficiency.

1. Tooling Costs

High-quality tooling can be expensive, impacting the initial investment in stamping machinery. Manufacturers can mitigate this by focusing on long-term cost savings through improved efficiency and reduced waste.

2. Material Limitations

Certain materials can pose challenges during the stamping process, such as springback and warping. Understanding material properties and selecting appropriate stamping techniques can alleviate these issues.

3. Quality Control

Maintaining consistent quality across production runs can be challenging. Implementing rigorous quality control measures and regular equipment maintenance will help ensure that high standards are met.

4. Skilled Labor Shortages

The manufacturing industry often faces a shortage of skilled labor. Investing in employee training and development, as well as leveraging automation, can help address this challenge.

5. Environmental Regulations

Manufacturers must navigate an increasingly complex landscape of environmental regulations. Adopting eco-friendly practices and materials can help companies remain compliant while appealing to environmentally conscious consumers.

The Future of High Precision Stamping Parts in Manufacturing

As technology continues to evolve, the future of high precision stamping parts looks promising. Manufacturers are likely to see significant advancements in the following areas:

1. Sustainability Practices

The shift toward more sustainable manufacturing practices will drive innovations in material sourcing and waste reduction strategies. Companies that embrace sustainability will gain a competitive edge in the market.

2. Integration of AI and Machine Learning

Artificial intelligence and machine learning will enhance decision-making processes in stamping operations. These technologies can predict maintenance needs, optimize production schedules, and improve quality control.

3. Customization and Personalization

As consumer preferences shift toward personalized products, high precision stamping will play a critical role in enabling customizable manufacturing at scale.

4. Advanced Robotics

The continued development of robotics will further enhance efficiency and precision in stamping processes, leading to lower production costs and improved safety.

5. Global Collaboration

In an increasingly interconnected world, global collaboration will enhance knowledge sharing and innovation across the stamping industry. This will lead to improved processes and the development of new technologies.

Conclusion

High precision stamping parts are integral to the success of modern production lines. Their ability to enhance product quality, reduce waste, and improve efficiency makes them indispensable in various industries. As technology advances, the role of high precision stamping will continue to evolve, offering manufacturers new opportunities for innovation and efficiency.

By understanding the significance of **high precision stamping parts**, their applications, and the latest technological advancements, companies can position themselves for success in an increasingly competitive market.

FAQs

1. What are high precision stamping parts used for?

High precision stamping parts are used in various industries for components like brackets, connectors, and electronic enclosures, ensuring accuracy and reliability in final products.

2. How does high precision stamping reduce production costs?

By minimizing material waste and optimizing processes, high precision stamping lowers production costs while maintaining quality, leading to overall cost savings.

3. What materials are commonly used in high precision stamping?

Common materials include steel, aluminum, brass, and various alloys, chosen based on the specific requirements of the application.

4. What advancements are being made in stamping technology?

Advancements include automation, smart manufacturing, improved tooling technologies, and the integration of AI, all aimed at enhancing efficiency and precision.

5. What challenges do manufacturers face with high precision stamping?

Manufacturers may face challenges such as tooling costs, material limitations, maintaining consistent quality, skilled labor shortages, and navigating environmental regulations. Solutions include investing in training, selecting appropriate materials, and implementing quality control measures.

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.