Gas Turbine Flow Meters: A Comprehensive Guide to Their Functionality

Gas Turbine Flow Meters: A Comprehensive Guide to Their Functionality In today’s fast-paced industrial environment, the ability to accurately measure fluid flow is paramount. Among the various tools available, gas turbine flow meters stand out for their precision and versatility. This comprehensive guide delves into what gas turbine flow meters are, how they operate, their advantages, applications

Gas Turbine Flow Meters: A Comprehensive Guide to Their Functionality

In today’s fast-paced industrial environment, the ability to accurately measure fluid flow is paramount. Among the various tools available, gas turbine flow meters stand out for their precision and versatility. This comprehensive guide delves into what gas turbine flow meters are, how they operate, their advantages, applications, and essential maintenance practices. By the end of this guide, you will have a thorough understanding of these critical instruments and their role in optimizing flow measurement processes.

Table of Contents

- What Are Gas Turbine Flow Meters?

- How Do Gas Turbine Flow Meters Work?

- Advantages of Gas Turbine Flow Meters

- Applications of Gas Turbine Flow Meters

- Selection Criteria for Gas Turbine Flow Meters

- Maintenance of Gas Turbine Flow Meters

- Common Issues and Troubleshooting

- The Future of Gas Turbine Flow Meters

- Conclusion

- FAQs About Gas Turbine Flow Meters

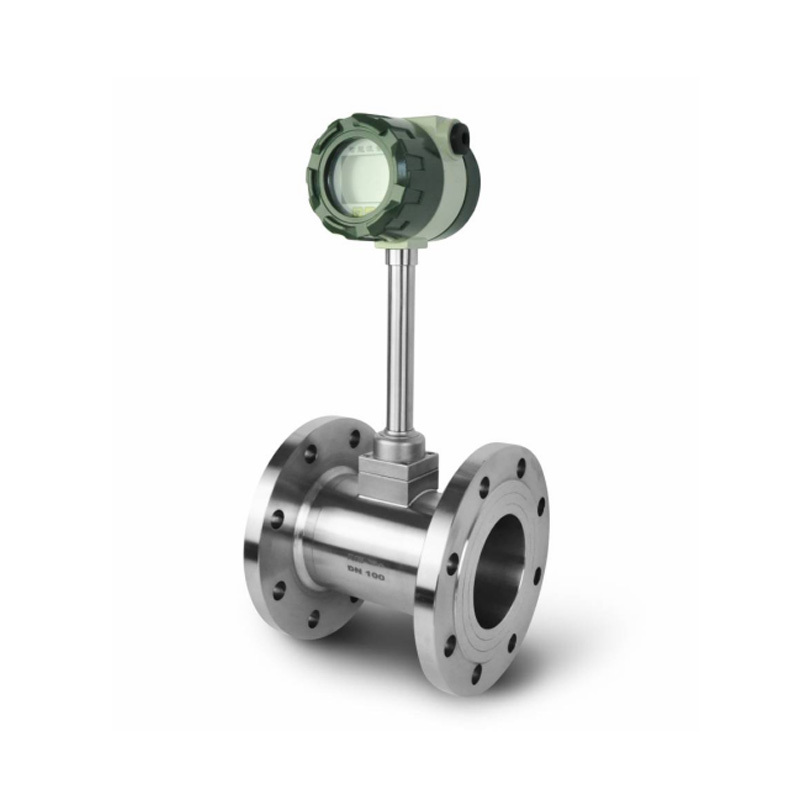

What Are Gas Turbine Flow Meters?

Gas turbine flow meters are sophisticated instruments designed to measure the flow rate of gases and liquids. These devices utilize a rotating turbine that spins in response to the flow of the fluid. The rate of rotation is directly proportional to the flow rate, allowing for precise measurements. This technology is especially beneficial in applications requiring high accuracy and reliability, making it a staple in the oil and gas, chemical, and water treatment industries.

How Do Gas Turbine Flow Meters Work?

The operating principle behind gas turbine flow meters is based on fluid dynamics. When a fluid flows through the meter, it encounters a turbine wheel. As the fluid passes over the blades of the turbine, it causes the turbine to rotate. This rotation is measured by a sensor, typically a magnetic or optical sensor, which generates a signal proportional to the turbine’s speed. The following steps outline the basic functioning of gas turbine flow meters:

The Flow Process

1. **Fluid Entry**: The fluid enters the flow meter through an inlet and is directed towards the turbine.

2. **Turbine Rotation**: The kinetic energy of the fluid causes the turbine to spin. The faster the fluid flows, the faster the turbine rotates.

3. **Signal Generation**: As the turbine spins, the sensor detects the rotational speed and generates an electronic signal.

4. **Flow Rate Calculation**: The electronic signal is processed by a flow computer or transmitter, which converts it into a flow rate reading.

Calibration and Accuracy

For optimal performance, gas turbine flow meters must be calibrated correctly. Calibration involves comparing the meter's readings to a known standard and adjusting the system to ensure accurate measurements. Regular calibration is essential, especially in applications with fluctuating flow conditions.

Advantages of Gas Turbine Flow Meters

Gas turbine flow meters offer several advantages that make them a preferred choice in various industries. Some of these benefits include:

High Accuracy and Repeatability

Gas turbine flow meters are renowned for their accuracy, often achieving measurement uncertainties of less than 1%. This high level of precision is crucial in industries where even minor discrepancies can lead to significant financial losses.

Wide Range of Applications

These meters are versatile and can handle various fluids, including gases, liquids, and even some slurries. Their adaptability makes them suitable for industries such as chemical processing, petroleum, and food and beverage.

Durability and Reliability

Designed to withstand harsh environments, gas turbine flow meters are robust and can operate effectively in extreme temperatures and pressures. Their durability ensures long service life and minimizes downtime.

Real-Time Monitoring

Modern gas turbine flow meters are equipped with digital displays and communication capabilities, allowing for real-time monitoring and data logging. This feature enhances operational efficiency and enables quick decision-making.

Applications of Gas Turbine Flow Meters

Gas turbine flow meters are widely used across various sectors due to their reliability and precision. Some common applications include:

Oil and Gas Industry

In the oil and gas sector, these meters measure the flow of crude oil, natural gas, and other hydrocarbons. Accurate flow measurement is essential for billing, inventory management, and process optimization.

Chemical Processing

Gas turbine flow meters are used in chemical plants to monitor the flow of raw materials and finished products. Their precision helps maintain process control and ensures product quality.

Water Treatment

In water treatment facilities, gas turbine flow meters measure the flow of water and chemicals used in purification processes. Accurate flow data is vital for ensuring compliance with environmental regulations.

Food and Beverage Industry

These meters are also employed in the food and beverage industry, where they monitor the flow of liquids such as juices, dairy products, and alcohol. Their sanitary design meets food safety standards.

Selection Criteria for Gas Turbine Flow Meters

Selecting the right gas turbine flow meter involves considering several factors to ensure optimal performance. Here are key criteria to evaluate:

Fluid Characteristics

Understand the nature of the fluid being measured, including viscosity, density, and temperature. These parameters will influence the meter's performance and accuracy.

Flow Rate Range

Determine the expected flow rate range. Gas turbine flow meters come in various sizes and specifications, so selecting one that matches your operational needs is crucial.

Installation Requirements

Consider the installation location and the necessary fittings to ensure a seamless integration into your existing system. Proper installation is essential for accurate measurements.

Calibration Needs

Examine the calibration requirements, including how often calibration is necessary and whether the device can be easily calibrated in situ.

Budget and Cost of Ownership

Evaluate the initial purchase cost alongside maintenance and operational costs. Investing in a high-quality gas turbine flow meter can lead to significant savings in efficiency and reduced downtime.

Maintenance of Gas Turbine Flow Meters

To ensure longevity and reliability, regular maintenance of gas turbine flow meters is essential. Here are some best practices:

Routine Inspections

Conduct regular inspections to check for wear and tear, especially on the turbine blades. Early detection of issues can prevent costly repairs and downtime.

Calibration Checks

Schedule calibration checks at regular intervals to maintain measurement accuracy. Calibration should be performed by qualified personnel using standard procedures.

Cleaning Procedures

Depending on the fluid being measured, cleaning may be required to prevent buildup on the turbine blades. Follow the manufacturer’s recommendations for cleaning procedures.

Documentation

Maintain a log of maintenance activities, including inspections, calibrations, and repairs. This documentation is critical for compliance and can help identify patterns that may indicate underlying issues.

Common Issues and Troubleshooting

Even with proper maintenance, issues may arise with gas turbine flow meters. Understanding common problems can facilitate quick resolution:

Inaccurate Readings

If the flow meter provides inconsistent or inaccurate readings, check for proper installation, calibration status, and any obstructions in the flow path.

Mechanical Failures

Mechanical failures, such as damaged turbine blades, may lead to operational issues. Regular inspections and prompt repairs can mitigate these risks.

Electrical Issues

Faulty wiring or sensor malfunctions can disrupt signal transmission. Ensure all electrical connections are secure and functioning correctly.

The Future of Gas Turbine Flow Meters

The evolution of technology continues to impact gas turbine flow meters significantly. Innovations such as smart sensors, IoT integration, and advanced data analytics are poised to enhance their functionality further. Future developments may include:

Enhanced Connectivity

The integration of IoT technology will allow gas turbine flow meters to communicate with other devices, enabling real-time data analysis and monitoring from remote locations.

Improved Accuracy and Efficiency

Advancements in materials and design may lead to even greater accuracy, enabling industries to optimize processes and reduce wastage.

Predictive Maintenance

Utilizing big data and machine learning algorithms can facilitate predictive maintenance, allowing operators to anticipate failures before they occur, thus minimizing downtime and enhancing productivity.

Conclusion

Gas turbine flow meters are indispensable tools in many industries, offering precision, reliability, and versatility in flow measurement. Understanding their functionality, advantages, and maintenance requirements is crucial for optimizing their performance. As technology continues to advance, gas turbine flow meters will likely become even more sophisticated, further enhancing their role in various applications. By selecting the right meter and adhering to maintenance best practices, organizations can achieve significant efficiencies and cost savings in their operations.

FAQs About Gas Turbine Flow Meters

1. What fluids can gas turbine flow meters measure?

Gas turbine flow meters can measure various fluids, including gases, liquids, and some slurries, making them versatile for multiple applications.

2. How often should gas turbine flow meters be calibrated?

The calibration frequency depends on the specific application and industry standards. Regular checks are recommended, typically every six months to a year.

3. Are gas turbine flow meters suitable for high-temperature applications?

Yes, many gas turbine flow meters are designed to operate effectively in high-temperature environments, but it is essential to check the specifications of the specific model.

4. What is the typical lifespan of a gas turbine flow meter?

With proper maintenance, gas turbine flow meters can last several years, often seven to ten years or more, depending on operating conditions.

5. Can gas turbine flow meters be used in hazardous environments?

Yes, many models are designed for use in hazardous environments, equipped with safety features to prevent ignition in explosive atmospheres.

Previous:

OEM

From precise design drawings, to rigorous production processes, to strict quality testing, we always uphold the spirit of ingenuity, the pursuit of every detail of the perfect. Our team has a wealth of industry experience and technical strength, according to your specific needs, to provide personalized customized services, to ensure that each product can meet your expectations.